What is a H2S Monitor?

A H2S monitor is a device designed to detect the presence of hydrogen sulfide in the air. It works by measuring the concentration of the gas in a given area and alerting personnel when it reaches a certain level. H2S monitors are typically used in industrial and hazardous environments, where the gas can be present in large quantities.

H2S monitors come in a variety of shapes and sizes, and are typically powered by either batteries or an AC power source. They can be used to detect hydrogen sulfide in both indoor and outdoor environments, making them ideal for monitoring H2S levels in a wide range of industrial settings.

The most common type of H2S monitor is a portable device that can be carried by workers or placed in strategic locations throughout an industrial facility. These devices are designed to detect the presence of hydrogen sulfide and alert personnel when it reaches a certain level. Many of these devices are also equipped with alarms that sound when H2S levels become too high, allowing workers to take action quickly to protect themselves.

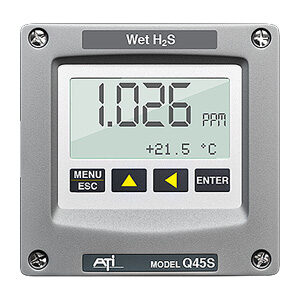

Other types of H2S monitors include fixed-location devices, which are designed to be installed in strategic locations throughout an industrial facility. These devices are typically more expensive than portable devices, but they are more accurate and reliable, making them ideal for long-term monitoring of H2S levels.

Finally, H2S monitors can also be used to detect hydrogen sulfide in water and other liquids. These devices are typically more expensive than air-monitoring devices, but they are essential for ensuring the safety of personnel in areas where liquid hydrogen sulfide is present.

Why is a H2S Monitor Necessary?

The use of H2S monitors is essential for ensuring the safety of personnel in industrial and hazardous environments. H2S is an extremely hazardous gas and can cause serious health problems if exposed to in high concentrations. Therefore, it’s essential to monitor H2S levels in these environments in order to protect personnel from potential exposure.

H2S monitors are designed to detect the presence of hydrogen sulfide in the air and alert personnel when it reaches a certain level. This allows personnel to take action quickly to protect themselves and others, reducing the risk of potential exposure.

In addition to helping protect personnel from H2S exposure, H2S monitors are also essential for preventing the spread of the gas. By monitoring H2S levels in the air, personnel can identify potential sources of the gas and take action to contain it. This helps prevent the gas from spreading to other areas of the facility, reducing the risk of potential exposure.

Finally, H2S monitors are also essential for identifying potential safety hazards in industrial environments. By monitoring hydrogen sulfide levels in the air, personnel can quickly identify potential sources of the gas and take action to reduce the risk of potential exposure. This helps keep personnel safe and reduces the risk of potential accidents and injuries.

H2S Exposure Limits

The Occupational Safety and Health Administration (OSHA) has established permissible exposure limits (PELs) for hydrogen sulfide in the workplace. These limits are designed to protect workers from potential health effects of the gas, and they vary depending on the concentration of the gas in the air.

The OSHA PEL for hydrogen sulfide is 10 parts per million (ppm) over an 8-hour period. This means that workers should not be exposed to concentrations of hydrogen sulfide higher than 10 ppm for more than 8 hours in any given day.

It’s important to note that these limits are not absolute and can be exceeded in certain circumstances. For example, if personnel are exposed to concentrations of hydrogen sulfide higher than 10 ppm for less than 15 minutes, then the PEL does not apply. However, it’s still important to use caution when working in areas where hydrogen sulfide is present, and personnel should always take necessary precautions to protect themselves.

Common Questions About H2S Monitors

There are a number of questions that people often have about H2S monitors. Here are some of the most common questions and their answers.

Q: How often should I check my H2S monitor?

A: The frequency at which you should check your H2S monitor depends on the type of monitor you have and the environment in which it is being used. Each organization and industry will require a minimum maintenance and calibration procedure which you should be familiar waith. At the very least most personal monitors are “bump Tested” on a daily basis. It’s also important to regularly check the batteries in portable monitors to ensure they are functioning properly.

Q: How accurate are H2S monitors?

A: The accuracy of H2S monitors varies depending on the type of monitor you have and the environment in which it is being used. Generally speaking, portable H2S monitors are less accurate than fixed-location monitors, but they are still reliable enough for most applications.

Q: How long do H2S monitors last?

A: The lifespan of a H2S monitor depends on the type of monitor you have and the environment in which it is being used.

H2S Monitor Maintenance

It’s important to regularly maintain your H2S monitor in order to ensure it is functioning properly. Here are some tips for maintaining your H2S monitor:

- Check the batteries in your portable H2S monitor regularly to make sure they are functioning properly.

- Calibrate your H2S monitor regularly to ensure it is providing accurate readings.

- Replace any parts of your H2S monitor that are worn or damaged, as this can affect its accuracy.

- Follow the manufacturer’s instructions for maintenance and repair of your H2S monitor.

By following these tips, you can ensure that your H2S monitor is functioning properly and providing accurate readings. This will help protect personnel from potential exposure to hydrogen sulfide and ensure a safe working environment.

Conclusion

Using a H2S monitor is essential for ensuring the safety of personnel in industrial and hazardous environments. H2S monitors are designed to detect the presence of hydrogen sulfide in the air and alert personnel when it reaches a certain level. This allows personnel to take action quickly to protect themselves and others, reducing the risk of potential exposure.

It’s also important to regularly maintain your H2S monitor in order to ensure it is functioning properly. This will help protect personnel from potential exposure to hydrogen sulfide and ensure a safe working environment.

By using a H2S monitor and following proper maintenance protocols, you can ensure the safety of personnel in industrial and hazardous environments and reduce the risk of potential exposure to hydrogen sulfide.