Home > Gas Detection > Toxic Gas Detection

UniSens universal 2-wire toxic gas detection transmitter handles 28 different gases, providing the most economical and flexible gas measurement system available today. Combining universal electronics, bench calibration capability, automatic sensor verification, fault detection and alarming, and superior sensor technology, UniSens is your best transmitter choice.

UniSens is designed for ambient toxic gas monitoring in all kinds of industrial environments: gas storage areas, gas compressor rooms, process piping galleries, rail car sidings, analyzer shacks, gas cabinets, chemical process areas, and more.

In fact, the UniSens transmitter can be used most anywhere that hazardous gas conditions might develop either through leakage or through natural buildup.

The companion memory assembly stores operational information and calibration constants, along with gas sensor identification, sensing module range, and software revision level. Complete sensing modules are housed in convenient snap-in packages that mate easily with UniSens transmitters.

This unique combination of sensor and memory lets you calibrate sensing modules with any UniSens transmitter. So instead of calibrating in the field, you can bench calibrate sensing modules with a spare transmitter; once the sensors are snapped into a field transmitter, their calibration constants upload automatically.

The UniSens microcomputer-controlled transmitter provides a local digital display and a 4–20 mA analog output proportional to gas concentration. It works with any ATI sensing module, configuring its own display and output range automatically based on data read from the module’s memory. Zero and calibration data is also read into memory, so the transmitter is automatically calibrated when it’s connected to a calibrated module.

Magnetic controls on the front of the transmitter allow field calibration, manual activation of the Auto-Test feature (if installed), and review of sensing module data including gas type, range, and number of successful Auto-Tests.

The transmitter can also act as an analog output simulator to facilitate complete loop testing. Outputs of 4.0, 12.0, and 20.0 mA are selectable via the front panel, along with a trouble signal of 3.6 mA. The transmitter is housed in a durable cast-aluminum shell with an 11-pin octal base for easy installation and removal. And since UniSens transmitters are 100% interchangeable, one unit can serve as a backup for every type of gas in use.

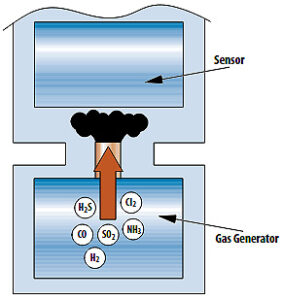

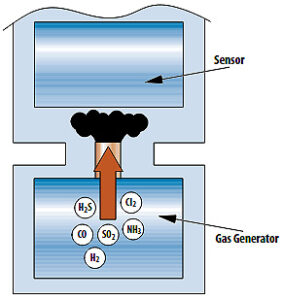

It’s a simple system. The Auto-Test gas generator is coupled to the end of the sensor as an integral part of the sensing module. Every 24 hours, the transmitter activates the generator and monitors the sensor for response. If the sensor responds properly, the system reverts to normal operation; if it fails, output is driven to 3.6 mA to signal trouble. (During testing, the output signal is held at the pre-test value.) The transmitter maintains a log of completed tests, and can display the time until the next scheduled test. An operator can manually activate Auto-Test, too.

Calibration Adapter: This fitting slides into the bottom of the splash guard and allows easy connection of zero air and span gas.

Flowcell Assembly: For applications requiring sample draw systems, the flowcell seals the sensing module and permits the addition of inlet and outlet fittings to pipe sample into and out of the sensor.

Model A12 | – | CC | – | DDDD | – | E | – | F | UniSens Transmitter |

*Indicates that Auto-Test is available for standard range.

| 10 – Bromine 0-1 (10) PPM* 11 – Chlorine 0-10 (100) PPM* 12 – Chlorine Dioxide 0-1 (10) PPM* 13 – Fluorine 0-1 (10) PPM* 14 – Ozone 0-1 (10) PPM* 15 – Ammonia 0-100 (500) PPM* 16 – Carbon Monoxide 0-100 (500) PPM* 18 – Hydrogen 0-2000 PPM (0-4%) 19 – Oxygen 0-25% (0-100%) 20 – Phosgene 0-1 (10) PPM 21 – Hydrogen Chloride 0-20 (100) PPM* 22 – Hydrogen Cyanide 0-20 (100) PPM* 23 – Hydrogen Fluoride 0-20 (100) PPM* 24 – Hydrogen Sulfide 0-50 (100) PPM* 25 – Nitric Oxide 0-50 (500) PPM | 26 – Nitrogen Dioxide 0-20 (100) PPM* 27 – Sulfur Dioxide 0-20 (100) PPM* 28 – Arsine 0-1000 PPB (0-10 PPM) 29 – Diborane 0-1000 PPB (0-10 PPM) 30 – Germane 0-1000 PPB (0-10 PPM) 31 – Hydrogen Selenide 0-1000 PPB (0-10 PPM) 32 – Phosphine 0-1000 PPB (0-10 PPM) 33 – Silane 0-10 PPM (0-1000 PPB) 34 – Hydrogen Peroxide 0-10 (100) PPM 35 – Iodine 0-1 (10) PPM* 36 – Acid Gases 0-10 (100) PPM 37 – ETO 0-20 (0-200) PPM 38 – Formaldehyde 0-20 (0-200) PPM 39 – Alcohol: Contact Us |

Code the measurement range using a 4-digit number representing the full scale value. For 0–10 PPM chlorine, the code would be 0010. For 0–100 PPM ammonia, the code would be 0100. The standard ranges are shown under Suffix C above. An alternate range is shown in parentheses. There is no added price for the alternate ranges.

1 – PPM

2 – PPB

3 – %

4 – %LEL

1 – Sensor without Auto-Test Generator

2 – Sensor with Auto-Test Generator

(Requires Splash Guard #45-0047)

45-0047 – Splash Guard (Required for Auto-Test)

00-0249 – Flowcell Assembly

00-0210 – Sensing Module Keeper

00-0248 – Calibration Adapter (Requires 45-0047)

| Gas Type: | Customer-selected from available list |

| Range: | Supplied with standard range for each gas unless otherwise specified |

| Display: | 4-1/2 digit LCD |

| Accuracy: | Generally ±5% of value, but limited by available calibration gas accuracy |

| Electronic Repeatability: | ±1% |

| Electronic Linearity: | ±0.5% |

| Zero drift: | Sensor dependent, but generally less than 2% of full scale per month, non-cumulative |

| Span drift: | Application dependent, but generally less than 3% per month. |

| Power: | 12–30 VDC |

| Output: | Loop-powered 4-20 mA, 675 ohms maximum at 24 VDC |

| Loop Simulation: | Operator selectable outputs of 4, 12, 20, and 3.6 mA (trouble indictor) |

| Enclosure: | NEMA 4X and Explosion-proof cast aluminum, Class 1, Div. 1, Groups B, C, & D, CSA approved |

| Controls: | Magnetic controls activated externally through glass window |

| Operating Temperature: | -30° to +55°C (except oxygen, which is -10° to +55°C) |

| Sensor: | Modular plug-in unit with calibration data, gas type, and range in sensor memory |

| Sensor Life: | Average greater than two years |

| Sensor Pressure Limits: | 7–30 PSIA (05–2 Bar) |

| Weight: | 4 lbs. (1.8 Kg.) |

UniSens universal 2-wire toxic gas detection transmitter handles 28 different gases, providing the most economical and flexible gas measurement system available today. Combining universal electronics, bench calibration capability, automatic sensor verification, fault detection and alarming, and superior sensor technology, UniSens is your best transmitter choice.

UniSens is designed for ambient toxic gas monitoring in all kinds of industrial environments: gas storage areas, gas compressor rooms, process piping galleries, rail car sidings, analyzer shacks, gas cabinets, chemical process areas, and more.

In fact, the UniSens transmitter can be used most anywhere that hazardous gas conditions might develop either through leakage or through natural buildup.

The companion memory assembly stores operational information and calibration constants, along with gas sensor identification, sensing module range, and software revision level. Complete sensing modules are housed in convenient snap-in packages that mate easily with UniSens transmitters.

This unique combination of sensor and memory lets you calibrate sensing modules with any UniSens transmitter. So instead of calibrating in the field, you can bench calibrate sensing modules with a spare transmitter; once the sensors are snapped into a field transmitter, their calibration constants upload automatically.

The UniSens microcomputer-controlled transmitter provides a local digital display and a 4–20 mA analog output proportional to gas concentration. It works with any ATI sensing module, configuring its own display and output range automatically based on data read from the module’s memory. Zero and calibration data is also read into memory, so the transmitter is automatically calibrated when it’s connected to a calibrated module.

Magnetic controls on the front of the transmitter allow field calibration, manual activation of the Auto-Test feature (if installed), and review of sensing module data including gas type, range, and number of successful Auto-Tests.

The transmitter can also act as an analog output simulator to facilitate complete loop testing. Outputs of 4.0, 12.0, and 20.0 mA are selectable via the front panel, along with a trouble signal of 3.6 mA. The transmitter is housed in a durable cast-aluminum shell with an 11-pin octal base for easy installation and removal. And since UniSens transmitters are 100% interchangeable, one unit can serve as a backup for every type of gas in use.

It’s a simple system. The Auto-Test gas generator is coupled to the end of the sensor as an integral part of the sensing module. Every 24 hours, the transmitter activates the generator and monitors the sensor for response. If the sensor responds properly, the system reverts to normal operation; if it fails, output is driven to 3.6 mA to signal trouble. (During testing, the output signal is held at the pre-test value.) The transmitter maintains a log of completed tests, and can display the time until the next scheduled test. An operator can manually activate Auto-Test, too.

Calibration Adapter: This fitting slides into the bottom of the splash guard and allows easy connection of zero air and span gas.

Flowcell Assembly: For applications requiring sample draw systems, the flowcell seals the sensing module and permits the addition of inlet and outlet fittings to pipe sample into and out of the sensor.

Model A12 | – | CC | – | DDDD | – | E | – | F | UniSens Transmitter |

*Indicates that Auto-Test is available for standard range.

| 10 – Bromine 0-1 (10) PPM* 11 – Chlorine 0-10 (100) PPM* 12 – Chlorine Dioxide 0-1 (10) PPM* 13 – Fluorine 0-1 (10) PPM* 14 – Ozone 0-1 (10) PPM* 15 – Ammonia 0-100 (500) PPM* 16 – Carbon Monoxide 0-100 (500) PPM* 18 – Hydrogen 0-2000 PPM (0-4%) 19 – Oxygen 0-25% (0-100%) 20 – Phosgene 0-1 (10) PPM 21 – Hydrogen Chloride 0-20 (100) PPM* 22 – Hydrogen Cyanide 0-20 (100) PPM* 23 – Hydrogen Fluoride 0-20 (100) PPM* 24 – Hydrogen Sulfide 0-50 (100) PPM* 25 – Nitric Oxide 0-50 (500) PPM | 26 – Nitrogen Dioxide 0-20 (100) PPM* 27 – Sulfur Dioxide 0-20 (100) PPM* 28 – Arsine 0-1000 PPB (0-10 PPM) 29 – Diborane 0-1000 PPB (0-10 PPM) 30 – Germane 0-1000 PPB (0-10 PPM) 31 – Hydrogen Selenide 0-1000 PPB (0-10 PPM) 32 – Phosphine 0-1000 PPB (0-10 PPM) 33 – Silane 0-10 PPM (0-1000 PPB) 34 – Hydrogen Peroxide 0-10 (100) PPM 35 – Iodine 0-1 (10) PPM* 36 – Acid Gases 0-10 (100) PPM 37 – ETO 0-20 (0-200) PPM 38 – Formaldehyde 0-20 (0-200) PPM 39 – Alcohol: Contact Us |

Code the measurement range using a 4-digit number representing the full scale value. For 0–10 PPM chlorine, the code would be 0010. For 0–100 PPM ammonia, the code would be 0100. The standard ranges are shown under Suffix C above. An alternate range is shown in parentheses. There is no added price for the alternate ranges.

1 – PPM

2 – PPB

3 – %

4 – %LEL

1 – Sensor without Auto-Test Generator

2 – Sensor with Auto-Test Generator

(Requires Splash Guard #45-0047)

45-0047 – Splash Guard (Required for Auto-Test)

00-0249 – Flowcell Assembly

00-0210 – Sensing Module Keeper

00-0248 – Calibration Adapter (Requires 45-0047)

| Gas Type: | Customer-selected from available list |

| Range: | Supplied with standard range for each gas unless otherwise specified |

| Display: | 4-1/2 digit LCD |

| Accuracy: | Generally ±5% of value, but limited by available calibration gas accuracy |

| Electronic Repeatability: | ±1% |

| Electronic Linearity: | ±0.5% |

| Zero drift: | Sensor dependent, but generally less than 2% of full scale per month, non-cumulative |

| Span drift: | Application dependent, but generally less than 3% per month. |

| Power: | 12–30 VDC |

| Output: | Loop-powered 4-20 mA, 675 ohms maximum at 24 VDC |

| Loop Simulation: | Operator selectable outputs of 4, 12, 20, and 3.6 mA (trouble indictor) |

| Enclosure: | NEMA 4X and Explosion-proof cast aluminum, Class 1, Div. 1, Groups B, C, & D, CSA approved |

| Controls: | Magnetic controls activated externally through glass window |

| Operating Temperature: | -30° to +55°C (except oxygen, which is -10° to +55°C) |

| Sensor: | Modular plug-in unit with calibration data, gas type, and range in sensor memory |

| Sensor Life: | Average greater than two years |

| Sensor Pressure Limits: | 7–30 PSIA (05–2 Bar) |

| Weight: | 4 lbs. (1.8 Kg.) |

WJF Instrumentation Ltd.

#5 3610 – 29th Street N.E.

Calgary, Alberta

Canada

T1Y 5Z7

Calgary Head Office

Toll-Free: (877)291-5572

Standard: (403)291-5570

Ontario & Maritimes Sales:

(905)809-6918