Home > Gas Detection > Modular Gas Detector

GasSens modular gas detection systems consist of individual modules that can be located where required. Sensor/transmitters, located in the area where gas leakage or buildup might occur, provide the basic measurement for the system. Sensor transmitters are available in either NEMA 4X or explosion-proof versions and can be supplied with ATI’s exclusive Auto-Test automatic sensor testing system, greatly reducing operator testing requirements.

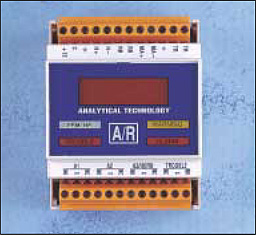

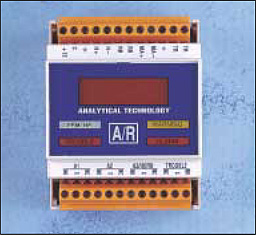

Receiver modules provide the electronic brains for the detection and alarm system. Each compact module includes a digital display of gas concentration, isolated analog output, and 4 relay outputs. Receivers may be located up to 1000 feet from sensor/transmitters for remote indication, or can provide local control functions such as valve shutoff while transmitting a 4-20 mA signal to remote displays or data loggers.

Universal power supply modules provide DC power to receivers. The power supply is housed in a compact module similar to the receiver, and will accept inputs from 85 to 265 volts, AC or DC, without adjustment. The power supply also provides a power failure relay and charging for an optional battery back-up unit.

Receiver modules provide an interface between the detection system and external alarming and data logging requirements. One module is used with each sensor/transmitter and includes a variety of features:

GasSens gas detection systems employ electrochemical sensors developed and manufactured by ATI. Expertise in electrochemistry and sensor design provides the foundation for leak detection systems that perform continuously with minimal maintenance. Sensors are rated for ambient temperatures from -25° to +50°C, allowing both indoor and outdoor applications. Excellent zero stability and high sensitivity and selectivity combine to make ATI sensors the best available on the market today.

Gas sensors are closely coupled to a digital transmitter for excellent noise immunity and the ability to transmit long distances using unshielded cable. The transmitter is powered from the receiver module and uses a unique cur- rent pulse position technique to send information to the receiver over a two wire connection. The receiver connection is not polarity sensitive, virtually eliminating the possibility of incorrect transmitter wiring. Sensor/transmitters can be located up to 1000 feet from receiver modules.

Sensor/transmitters are housed in shielded NEMA 4X enclosures for use in almost any industrial environment and are designed to meet intrinsic safety standards. An explosion-proof version of the transmitter is also available for applications where this type of protection is preferred. Combustible gas transmitters are always explosion-proof.

A major expense in gas detection systems is the cost of regular testing to ensure that sensors are responding. This requires a technician to inspect sensors weekly and apply a small amount of gas manually to check response. ATI has developed a unique system to reduce this maintenance requirement.

Available on most ATI digital sensor/transmitters is an option called “Auto-Test.” This option consists of an electrochemical gas generator closely coupled to the sensor. Every 24 hours, the receiver automatically activates the generator, producing a small amount of gas that diffuses into the sensor, just as it would if a gas leak occurred. The microcomputer in the receiver analyzes the output of the transmitter to determine that the sensor is responding normally. When proper sensor response is detected, the generator is turned off and the system goes back to normal operation. If no sensor response is detected, the TROUBLE light on the receiver will flash and the trouble relay will activate. During testing, alarm relays are inhibited so that external alarms are not activated.

The Auto-Test feature ensures that each sensor is regularly tested with gas. Premature sensor failure or blockage of the sensor membrane is quickly detected. In addition, self-testing will alert maintenance personnel when a sensor has reached the end of its useful life. Since sensors normally last any- where from 12 months to over 3 years, this feature allows users to determine when sensor replacement is needed

To meet the needs of users throughout the world, ATI has developed a compact universal power supply in a DIN rail module similar to the receiver. The power supply will accept any AC or DC input from 85 to 265 volts, without adjustment. No jumper changes or selection switches are required, and large variations in input voltage do not affect power supply operation. This power supply is suitable for operation of one or two receiver modules.

The power supply provides three 12 VDC output connections, two of which are designated for receiver module connection. A third connection is provided to automatically charge the optional external battery back-up system. The power supply module is protected by a fuse conveniently located in a removable holder accessible from outside the module. For external power failure indication, the power supply contains a SPDT relay. The relay is normally energized, and de-energizes on power failure.

Battery back-up systems are used in gas detection applications to ensure that detectors remain operable, even when AC power fails. ATI offers a separate battery back-up unit that maintains power to detection equipment in the event of a power interruption. The battery back-up system consists of a rechargeable sealed lead acid battery housed in a NEMA 4X enclosure. An electronic circuit attached to the battery controls the charging rate and will disconnect the battery from the system if the battery voltage drops to a level where battery damage might occur. Charging is provided by the power supply module.

Battery back-up units will operate a single point detector for a minimum of 12 hours and an average of 24 hours. Two point systems will be maintained for 6 hours minimum and an average of 12 hours. The actual battery back-up time depends on whether the LED display is operated in high intensity mode and whether relays are in fail-safe mode (normally energized).

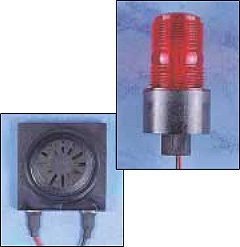

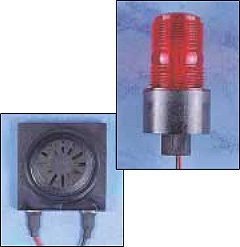

A weatherproof piezoelectric audible horn is available for all gas detectors. The horn operates from 12 VDC supplied by the power supply module and can be activated from single or multiple receiver modules. The horn mounts easily in one of the enclosure knockouts, and produces an 85 dB signal for local alarming.

A 12 VDC strobe is available for enhanced visual alarm indication. The strobe uses a xenon lamp with a bright 1/2-million CP flash firing 70 times/minute. Strobe housing is weatherproof lexan with red lens, and mounts to 1/2″ conduit.

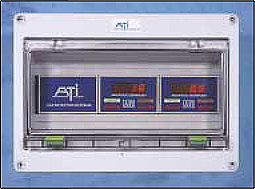

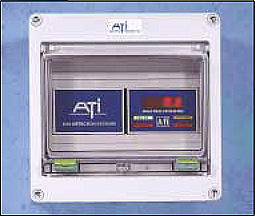

A variety of NEMA 4X enclosures are available to house receiver and power supply modules. ATI offers standard enclosures to house up to 6 modules, and can supply large enclosures for systems requiring more points of detection. System integrators can use standard 35 mm DIN rail mounting modules in their own enclosure.

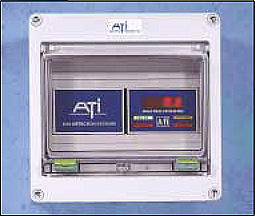

Single Module Enclosure: Houses a single receiver module for use in DC powered applications where the user supplies the DC power to the system.

Two Module Enclosure: Houses two receivers or one receiver and one power supply. Normally used for single point AC powered detectors.

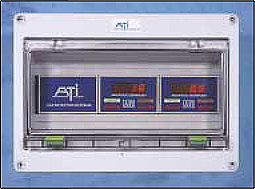

Three Module Enclosure: Accommodates two receivers and power supply or three receivers. Used mainly for two point detection systems.

Six Module Enclosure: Suitable for two power supplies and four receivers or six receivers. This enclosure is used primarily for four point gas detection systems.

Modular Gas Detector Special Enclosures: Custom enclosures are available to handle systems of any size. We (WJF Instrumentation) can assist with system designs for larger applications.

Model A14/A11 | – | CC | – | DDDD | – | E | – | F | Receiver Module + Sensor/Transmitter |

| Suffix CC – Gas Type – Standard range shown in parentheses | ||

| 10 – Bromine (0-2 PPM)* 11 – Chlorine (0-10 PPM)* 12 – Chlorine Dioxide (0-2 PPM)* 13 – Fluorine (0-2 PPM)* 14 – Ozone (0-2 PPM)* 15 – Ammonia (0-100 PPM)* 16 – Carbon Monoxide (0-100 PPM)* 17 – Combustible Gas (0-100% LEL) 18 – Hydrogen (0-4%) 19 – Oxygen (0-25%) | 20 – Phosgene (0-2 PPM) 21- Hydrogen Chloride (0-20 PPM)* 22 – Hydrogen Cyanide (0-20 PPM)* 23 – Hydrogen Fluoride (0-20 PPM)* 24 – Hydrogen Sulfide (0-50 PPM)* 25 – Nitric Oxide (0-100 PPM) 26 – Nitrogen Dioxide (0-20 PPM)* 27 – Sulfur Dioxide (0-20 PPM)* 28 – Arsine (0-1000 PPB) 29 – Diborane (0-1000 PPB) | 30 – Germane (0-1000 PPB) 31 – Hydrogen Selenide (0-1000 PPB) 32 – Phosphine (0-1000 PPB) 33 – Silane (0-10 PPM) 34 – Hydrogen Peroxide (0-10 PPM) 35 – Iodine (0-2 PPM)* 36 – Acid Gases (0-10 PPM)* 37 – ETO (0-20 PPM)* 38 – Formaldehyde (0-20 PPM)* 39 – Alcohol: Consult With Us |

* Indicates Auto-Test option available for standard range or below.

Suffix DDDD – Range

Code the measurement range using a four digit number. The standard ranges are shown under Suffix C above. For 0-10 PPM chlorine, the code would be 0010. For 0-200 PPM ammonia, the code would be 0200.

Suffix E – Units of Measurement

1 – PPM

2 – PPB

3 – %

4 – % LEL

Suffix F – Auto-Test System

1 – Without sensor Auto-Test function

2 – With sensor self-test

| Options and System Enclosures | |

| 80-0005 Single Module Enclosure 80-0006 Two Module Enclosure 80-0007 Three Module Enclosure 80-0033 Large Three Module Enclosure 80-0008 Six Module Enclosure 80-0027 Large Six Module Enclosure 80-0024 Nine Module Enclosure 80-0026 Twelve Module Enclosure 00-0055 Power Supply Module 28-0004 65 Watt Power Supply (for up to 12 Receivers) 00-0057 Battery Backup Unit 00-0058 Audible Horn 35-0008 Horn, Industrial External 120 VAC | 35-0002 Strobe with red lens, 12 VDC 35-0005 Strobe with red lens, 120 VAC 00-0118 Calibration adapter for A10 sensor 00-0258 Calibration adapter for C10 explosion-proof sensors (combustibles) 00-0261 Remote calibration adapter for combustible sensor 45-0046 Rain Shield for C10 explosion-proof sensors (combustibles) 00-0253 Flowcell assembly for A10 sensor 00-0298 Flowcell assembly for C10 explosion-proof sensors |

| 00-1000* Bromine Br2, 0-1/5 ppm (00-1538) 00-1001* Bromine Br2, 0-5/200 ppm (00-1538, 20 max.) 00-1002* Chlorine Cl2, 0-1/5 ppm (00-1538) 00-1003* Chlorine Cl2, 0-5/200 ppm (00-1538, 20 max.) 00-1004* Chlorine dioxide ClO2, 0-1/5 ppm (00-1538) 00-1005* Chlorine dioxide ClO2, 0-5/200 ppm (00-1538, 20 max.) 00-1359 Chlorine dioxide ClO2, 200/1000 ppm 00-1425* Chlorine dioxide ClO2, 0-1/5 ppm (low Cl2) (00-1538) 00-1006* Fluorine F2, 0-1/5 ppm (00-1538) 00-1007* Fluorine F2, 0-5/200 (00-1538, 20 max.) 00-1008* Ozone O3, 0-1/5 ppm (00-1538) 00-1009* Ozone O3, 0-5/200 ppm (00-1538, 20 max.) 00-1358 Ozone O3, 200/1000 ppm 00-1163 Ozone O3, 500/2000 ppb (00-1538) 00-1010* Ammonia NH3, 0-50/500 ppm (00-1539, 100 max.) 00-1011 Ammonia NH3, 0-500/2000 ppm 00-1012* Carbon monoxide CO, 0-50/1000 ppm (00-1540, 100 max.) 00-1013 Hydrogen H2, 0-1/10% 00-1041 Hydrogen H2, 0-500/2000 ppm 00-1014 Oxygen O2, 0-5/25% 00-1015 Phosgene COCl2, 0-1/5 ppm 00-1016 Phosgene COCl2, 0-5/100 ppm 00-1017* Hydrogen chloride HCl, 0-10/200 ppm (00-1541, 20 max.) 00-1018* Hydrogen cyanide HCN, 0-10/200 ppm (00-1611, 20 max.) 00-1019* Hydrogen fluoride HF, 0-10/200 ppm (00-1538, 20 max.) 00-1020* Hydrogen sulfide H2S, 0-10/200 ppm (00-1541, 100 max.) 00-1469 Hydrogen sulfide H2S, 200/1000 ppm 00-1021 Nitric oxide NO, 0-50/500 ppm 00-1022* Nitrogen dioxide NO2, 0-10/200 ppm (00-1538, 20 max.) 00-1023* Sulfur dioxide SO2, 0-10/500 ppm (00-1542, 20 max.) | 00-1024 Arsine AsH3, 0-500/2000 ppb 00-1025 Arsine AsH3, 0-10/200 ppm 00-1026 Diborane B2H6, 0-500/2000 ppb 00-1027 Diborane B2H6, 0-10/200 ppm 00-1028 Germane GeH4, 0-500/2000 ppb 00-1029 Germane GeH4, 0-10/200 ppm 00-1030 Hydrogen selenide H2Se, 0-500/2000 ppb 00-1031 Hydrogen selenide H2Se, 0-10/200 ppm 00-1032 Phosphine PH3, 0-500/2000 ppb 00-1033 Phosphine PH3, 0-10/200 ppm 00-1034 Phosphine PH3, 0-200/2000 ppm 00-1035 Silane SiH4, 0-10/200 ppm 00-1036* Iodine I2, 0-1/5 ppm (00-1538) 00-1037* Iodine I2, 0-5/200 ppm (00-1538, 20 max.) 00-1038* Acid Gas, 0-10/200 ppm (00-1538,20 max) 00-1039* Ethylene Oxide ETO, 0-20/200 ppm (00-1540, 20 max.) 00-1040 Formaldehyde HCOH, 0-20/200 ppm (00-1540, 20 max.) 00-1349 Formaldehyde HCOH, 500/2000 ppm 00-1042 Hydrogen peroxide H2O2, 0-10/100 ppm (00-1542) 00-1169 Hydrogen peroxide H2O2, 200/2000 ppm 00-1043 Alcohol, 0-50/500 ppm 00-1044 Alcohol, 0-500/2000 ppm 00-1057 Acetylene C2H2, 0-50/500 ppm 00-1181 Nitric oxide NOX, 0-50/500 ppm 00-1450* Dimethylacetamide DMA, 100/200 ppm (00-1539, 100 max.) 00-1455* Hydrogen bromide HBr, 10/200 ppm (00-1538, 20 max.) 00-1516 hydrocarbon HC Sensor – Consult Factory) 00-1045 Acetic acid CH3COOH, 100/500 ppm 00-1704 Peracetic acid PAA Vapor, 1/5 ppm 00-1705 Peracetic acid PAA Vapor, 10/100 ppm 00-1883 IR CH4, 0-20/100% LEL ** 00-1886 IR CO2, 0-0.2/1.5% |

** 00-1883 LEL CH4 sensor also responds to many other hydrocarbons. Response to other hydrocarbons is not 1:1 with CH4. Contact us for k factor data.

Receiver Module |

|

| Construction Display: | 4 digit LED, sunlight readable |

| Input: | Digital signal, 2 wire connection to remote sensor/transmitter |

| Output: | Isolated 4-20 mA DC, 1000 ohms maximum load |

| Alarms: | Two adjustable concentration alarms, set points adjustable from 5-100% of range |

| Alarm Indicators: | High intensity LED bars for WARNING (low set- point) and ALARM (high setpoint) |

| Indicator Function: | WARNING indicator non-latching, ALARM latching |

| Alarm Relays: | Three assignable alarm relays, 10 A, 120 VAC (5 A, 250 VAC) resistive Alarm relays assignable to either alarm set point |

| Relay Function: | Configurable for normal/fail-safe, latching/non- latching, and fast/slow operation |

| Relay & Indicator Reset: | Activated from front panel switch or through remote reset |

| Trouble Alarm: | Front panel LED indicator and SPDT, 10 A, 120 VAC (5A, 250 VAC) resistive relay; Relay factory set to fail-safe operation |

| Trouble Function: | Indicates loss of sensor/transmitter input or failure of sensor Auto-Test (if in use) |

| Gas Indicator: | LED bar on front panel with gas symbol overlay |

| Mounting: | Module mounts to 35 x 7.5 mm DIN rail |

| Electrical Connection: | Quick disconnect plug-in terminal blocks |

| Module Enclosure: | Noryl |

| Size: | 2.8″W x 3.6″L x 2.3″D (70 mm x 90 mm x 58 mm) |

| Operating Temperature: | -40° to +55°C |

| Humidity: | 0-99% non-condensing |

| Power: | 9-15 VDC, 300 mA maximum |

Module Enclosures |

|

| Single Module Enclosure: | NEMA 4X polystyrene, 4.33″W x 7.09″H x 4.33″D (110 x 180 x 110 mm) |

| Two Module Enclosure: | NEMA 4X polystyrene, 7.17″W x 7.09″H x 4.33″D (182 x 180 x 110 mm) |

| Three Module Enclosure: | NEMA 4X polystyrene, 10.0″W x 7.09″H x 4.33″D (254 x 180 x 110 mm) |

| Six Module Enclosure: | NEMA 4X polystyrene, 10.0″W x 14.21″H x 4.33″D (254 x 361 x 110 mm) |

Sensor/Transmitter |

|

| Measurement: | Gas type and range customer specified |

| Transmitter Type: | Two wire system, current pulse position signal |

| Sensor: | Electrochemical gas diffusion type (manufactured by ATI) |

| Accuracy: | Generally ±5% of value, but limited by available calibration of gas accuracy. |

| Zero Drift: | Sensor dependent but normally less than 2% per month, non-cumulative |

| Enclosure: | NEMA 4X polystyrene |

| Optional Enclosure: | Explosion-proof cast aluminum, Class I, Division I, Group B, C, & D |

| Electrical Connection: | Quick disconnect terminal blocks (two wires without polarity) |

| Connection Distance: | Up to 1000 feet (300 m) to receiver |

| Operating Temperature: | -25° to +55°C (-5° for oxygen) |

| Humidity: | 0-95% non-condensing |

| Option: | Sensor Auto-Test (available for most gases) |

| Size (Sensor Transmitter with Auto-Test): | 3.7″L x 6.5″W x 2.2″D (94 mm x 163 mm x 57 mm) |

| Power: | 12 VDC from receiver module |

Power Supply Module |

|

| Input Voltage: | 85-265 VAC, 50/60 Hz, or 85-265 VDC, self regulating |

| Output Voltage: | Regulated 13.7 VDC, 1A |

| Output Connection: | 3 separate connections, two for receiver modules, and one for external battery back-up |

| Alarm: | Loss of input power alarm relay, SPDT 10 A, 120 VAC (5A, 250 VAC) resistive |

| Operating Temperature: | -40° to +55°C |

| Humidity: | 0-99% non-condensing |

| Module Enclosure: | Noryl |

| Size: | 2.8″W x 3.6″L x 2.3″D (70mm x 90 mm x 58 mm) |

| Electrical Connection: | Quick disconnect terminal blocks |

| Mounting: | Module mounts to 35 x 7.5 mm DIN rail |

Battery Back-Up | |

| Battery: | 12 VDC, 4 Ampere hour |

| Charge Control: | Current limited to .75 A max. |

| Low Voltage Cutoff: | Relay disconnect at 10 VDC |

| Fault Protection: | Relay disconnect on shorted charger wiring |

| Enclosure: | NEMA 4X polystyrene |

| Size: | 4.33”W x 7.09”L x 3.54”D (110 mm x 180 mm x 90 mm) |

GasSens modular gas detection systems consist of individual modules that can be located where required. Sensor/transmitters, located in the area where gas leakage or buildup might occur, provide the basic measurement for the system. Sensor transmitters are available in either NEMA 4X or explosion-proof versions and can be supplied with ATI’s exclusive Auto-Test automatic sensor testing system, greatly reducing operator testing requirements.

Receiver modules provide the electronic brains for the detection and alarm system. Each compact module includes a digital display of gas concentration, isolated analog output, and 4 relay outputs. Receivers may be located up to 1000 feet from sensor/transmitters for remote indication, or can provide local control functions such as valve shutoff while transmitting a 4-20 mA signal to remote displays or data loggers.

Universal power supply modules provide DC power to receivers. The power supply is housed in a compact module similar to the receiver, and will accept inputs from 85 to 265 volts, AC or DC, without adjustment. The power supply also provides a power failure relay and charging for an optional battery back-up unit.

Receiver modules provide an interface between the detection system and external alarming and data logging requirements. One module is used with each sensor/transmitter and includes a variety of features:

GasSens gas detection systems employ electrochemical sensors developed and manufactured by ATI. Expertise in electrochemistry and sensor design provides the foundation for leak detection systems that perform continuously with minimal maintenance. Sensors are rated for ambient temperatures from -25° to +50°C, allowing both indoor and outdoor applications. Excellent zero stability and high sensitivity and selectivity combine to make ATI sensors the best available on the market today.

Gas sensors are closely coupled to a digital transmitter for excellent noise immunity and the ability to transmit long distances using unshielded cable. The transmitter is powered from the receiver module and uses a unique cur- rent pulse position technique to send information to the receiver over a two wire connection. The receiver connection is not polarity sensitive, virtually eliminating the possibility of incorrect transmitter wiring. Sensor/transmitters can be located up to 1000 feet from receiver modules.

Sensor/transmitters are housed in shielded NEMA 4X enclosures for use in almost any industrial environment and are designed to meet intrinsic safety standards. An explosion-proof version of the transmitter is also available for applications where this type of protection is preferred. Combustible gas transmitters are always explosion-proof.

A major expense in gas detection systems is the cost of regular testing to ensure that sensors are responding. This requires a technician to inspect sensors weekly and apply a small amount of gas manually to check response. ATI has developed a unique system to reduce this maintenance requirement.

Available on most ATI digital sensor/transmitters is an option called “Auto-Test.” This option consists of an electrochemical gas generator closely coupled to the sensor. Every 24 hours, the receiver automatically activates the generator, producing a small amount of gas that diffuses into the sensor, just as it would if a gas leak occurred. The microcomputer in the receiver analyzes the output of the transmitter to determine that the sensor is responding normally. When proper sensor response is detected, the generator is turned off and the system goes back to normal operation. If no sensor response is detected, the TROUBLE light on the receiver will flash and the trouble relay will activate. During testing, alarm relays are inhibited so that external alarms are not activated.

The Auto-Test feature ensures that each sensor is regularly tested with gas. Premature sensor failure or blockage of the sensor membrane is quickly detected. In addition, self-testing will alert maintenance personnel when a sensor has reached the end of its useful life. Since sensors normally last any- where from 12 months to over 3 years, this feature allows users to determine when sensor replacement is needed

To meet the needs of users throughout the world, ATI has developed a compact universal power supply in a DIN rail module similar to the receiver. The power supply will accept any AC or DC input from 85 to 265 volts, without adjustment. No jumper changes or selection switches are required, and large variations in input voltage do not affect power supply operation. This power supply is suitable for operation of one or two receiver modules.

The power supply provides three 12 VDC output connections, two of which are designated for receiver module connection. A third connection is provided to automatically charge the optional external battery back-up system. The power supply module is protected by a fuse conveniently located in a removable holder accessible from outside the module. For external power failure indication, the power supply contains a SPDT relay. The relay is normally energized, and de-energizes on power failure.

Battery back-up systems are used in gas detection applications to ensure that detectors remain operable, even when AC power fails. ATI offers a separate battery back-up unit that maintains power to detection equipment in the event of a power interruption. The battery back-up system consists of a rechargeable sealed lead acid battery housed in a NEMA 4X enclosure. An electronic circuit attached to the battery controls the charging rate and will disconnect the battery from the system if the battery voltage drops to a level where battery damage might occur. Charging is provided by the power supply module.

Battery back-up units will operate a single point detector for a minimum of 12 hours and an average of 24 hours. Two point systems will be maintained for 6 hours minimum and an average of 12 hours. The actual battery back-up time depends on whether the LED display is operated in high intensity mode and whether relays are in fail-safe mode (normally energized).

A weatherproof piezoelectric audible horn is available for all gas detectors. The horn operates from 12 VDC supplied by the power supply module and can be activated from single or multiple receiver modules. The horn mounts easily in one of the enclosure knockouts, and produces an 85 dB signal for local alarming.

A 12 VDC strobe is available for enhanced visual alarm indication. The strobe uses a xenon lamp with a bright 1/2-million CP flash firing 70 times/minute. Strobe housing is weatherproof lexan with red lens, and mounts to 1/2″ conduit.

A variety of NEMA 4X enclosures are available to house receiver and power supply modules. ATI offers standard enclosures to house up to 6 modules, and can supply large enclosures for systems requiring more points of detection. System integrators can use standard 35 mm DIN rail mounting modules in their own enclosure.

Single Module Enclosure: Houses a single receiver module for use in DC powered applications where the user supplies the DC power to the system.

Two Module Enclosure: Houses two receivers or one receiver and one power supply. Normally used for single point AC powered detectors.

Three Module Enclosure: Accommodates two receivers and power supply or three receivers. Used mainly for two point detection systems.

Six Module Enclosure: Suitable for two power supplies and four receivers or six receivers. This enclosure is used primarily for four point gas detection systems.

Modular Gas Detector Special Enclosures: Custom enclosures are available to handle systems of any size. We (WJF Instrumentation) can assist with system designs for larger applications.

Model A14/A11 | – | CC | – | DDDD | – | E | – | F | Receiver Module + Sensor/Transmitter |

| Suffix CC – Gas Type – Standard range shown in parentheses | ||

| 10 – Bromine (0-2 PPM)* 11 – Chlorine (0-10 PPM)* 12 – Chlorine Dioxide (0-2 PPM)* 13 – Fluorine (0-2 PPM)* 14 – Ozone (0-2 PPM)* 15 – Ammonia (0-100 PPM)* 16 – Carbon Monoxide (0-100 PPM)* 17 – Combustible Gas (0-100% LEL) 18 – Hydrogen (0-4%) 19 – Oxygen (0-25%) | 20 – Phosgene (0-2 PPM) 21- Hydrogen Chloride (0-20 PPM)* 22 – Hydrogen Cyanide (0-20 PPM)* 23 – Hydrogen Fluoride (0-20 PPM)* 24 – Hydrogen Sulfide (0-50 PPM)* 25 – Nitric Oxide (0-100 PPM) 26 – Nitrogen Dioxide (0-20 PPM)* 27 – Sulfur Dioxide (0-20 PPM)* 28 – Arsine (0-1000 PPB) 29 – Diborane (0-1000 PPB) | 30 – Germane (0-1000 PPB) 31 – Hydrogen Selenide (0-1000 PPB) 32 – Phosphine (0-1000 PPB) 33 – Silane (0-10 PPM) 34 – Hydrogen Peroxide (0-10 PPM) 35 – Iodine (0-2 PPM)* 36 – Acid Gases (0-10 PPM)* 37 – ETO (0-20 PPM)* 38 – Formaldehyde (0-20 PPM)* 39 – Alcohol: Consult With Us |

* Indicates Auto-Test option available for standard range or below.

Suffix DDDD – Range

Code the measurement range using a four digit number. The standard ranges are shown under Suffix C above. For 0-10 PPM chlorine, the code would be 0010. For 0-200 PPM ammonia, the code would be 0200.

Suffix E – Units of Measurement

1 – PPM

2 – PPB

3 – %

4 – % LEL

Suffix F – Auto-Test System

1 – Without sensor Auto-Test function

2 – With sensor self-test

| Options and System Enclosures | |

| 80-0005 Single Module Enclosure 80-0006 Two Module Enclosure 80-0007 Three Module Enclosure 80-0033 Large Three Module Enclosure 80-0008 Six Module Enclosure 80-0027 Large Six Module Enclosure 80-0024 Nine Module Enclosure 80-0026 Twelve Module Enclosure 00-0055 Power Supply Module 28-0004 65 Watt Power Supply (for up to 12 Receivers) 00-0057 Battery Backup Unit 00-0058 Audible Horn 35-0008 Horn, Industrial External 120 VAC | 35-0002 Strobe with red lens, 12 VDC 35-0005 Strobe with red lens, 120 VAC 00-0118 Calibration adapter for A10 sensor 00-0258 Calibration adapter for C10 explosion-proof sensors (combustibles) 00-0261 Remote calibration adapter for combustible sensor 45-0046 Rain Shield for C10 explosion-proof sensors (combustibles) 00-0253 Flowcell assembly for A10 sensor 00-0298 Flowcell assembly for C10 explosion-proof sensors |

| 00-1000* Bromine Br2, 0-1/5 ppm (00-1538) 00-1001* Bromine Br2, 0-5/200 ppm (00-1538, 20 max.) 00-1002* Chlorine Cl2, 0-1/5 ppm (00-1538) 00-1003* Chlorine Cl2, 0-5/200 ppm (00-1538, 20 max.) 00-1004* Chlorine dioxide ClO2, 0-1/5 ppm (00-1538) 00-1005* Chlorine dioxide ClO2, 0-5/200 ppm (00-1538, 20 max.) 00-1359 Chlorine dioxide ClO2, 200/1000 ppm 00-1425* Chlorine dioxide ClO2, 0-1/5 ppm (low Cl2) (00-1538) 00-1006* Fluorine F2, 0-1/5 ppm (00-1538) 00-1007* Fluorine F2, 0-5/200 (00-1538, 20 max.) 00-1008* Ozone O3, 0-1/5 ppm (00-1538) 00-1009* Ozone O3, 0-5/200 ppm (00-1538, 20 max.) 00-1358 Ozone O3, 200/1000 ppm 00-1163 Ozone O3, 500/2000 ppb (00-1538) 00-1010* Ammonia NH3, 0-50/500 ppm (00-1539, 100 max.) 00-1011 Ammonia NH3, 0-500/2000 ppm 00-1012* Carbon monoxide CO, 0-50/1000 ppm (00-1540, 100 max.) 00-1013 Hydrogen H2, 0-1/10% 00-1041 Hydrogen H2, 0-500/2000 ppm 00-1014 Oxygen O2, 0-5/25% 00-1015 Phosgene COCl2, 0-1/5 ppm 00-1016 Phosgene COCl2, 0-5/100 ppm 00-1017* Hydrogen chloride HCl, 0-10/200 ppm (00-1541, 20 max.) 00-1018* Hydrogen cyanide HCN, 0-10/200 ppm (00-1611, 20 max.) 00-1019* Hydrogen fluoride HF, 0-10/200 ppm (00-1538, 20 max.) 00-1020* Hydrogen sulfide H2S, 0-10/200 ppm (00-1541, 100 max.) 00-1469 Hydrogen sulfide H2S, 200/1000 ppm 00-1021 Nitric oxide NO, 0-50/500 ppm 00-1022* Nitrogen dioxide NO2, 0-10/200 ppm (00-1538, 20 max.) 00-1023* Sulfur dioxide SO2, 0-10/500 ppm (00-1542, 20 max.) | 00-1024 Arsine AsH3, 0-500/2000 ppb 00-1025 Arsine AsH3, 0-10/200 ppm 00-1026 Diborane B2H6, 0-500/2000 ppb 00-1027 Diborane B2H6, 0-10/200 ppm 00-1028 Germane GeH4, 0-500/2000 ppb 00-1029 Germane GeH4, 0-10/200 ppm 00-1030 Hydrogen selenide H2Se, 0-500/2000 ppb 00-1031 Hydrogen selenide H2Se, 0-10/200 ppm 00-1032 Phosphine PH3, 0-500/2000 ppb 00-1033 Phosphine PH3, 0-10/200 ppm 00-1034 Phosphine PH3, 0-200/2000 ppm 00-1035 Silane SiH4, 0-10/200 ppm 00-1036* Iodine I2, 0-1/5 ppm (00-1538) 00-1037* Iodine I2, 0-5/200 ppm (00-1538, 20 max.) 00-1038* Acid Gas, 0-10/200 ppm (00-1538,20 max) 00-1039* Ethylene Oxide ETO, 0-20/200 ppm (00-1540, 20 max.) 00-1040 Formaldehyde HCOH, 0-20/200 ppm (00-1540, 20 max.) 00-1349 Formaldehyde HCOH, 500/2000 ppm 00-1042 Hydrogen peroxide H2O2, 0-10/100 ppm (00-1542) 00-1169 Hydrogen peroxide H2O2, 200/2000 ppm 00-1043 Alcohol, 0-50/500 ppm 00-1044 Alcohol, 0-500/2000 ppm 00-1057 Acetylene C2H2, 0-50/500 ppm 00-1181 Nitric oxide NOX, 0-50/500 ppm 00-1450* Dimethylacetamide DMA, 100/200 ppm (00-1539, 100 max.) 00-1455* Hydrogen bromide HBr, 10/200 ppm (00-1538, 20 max.) 00-1516 hydrocarbon HC Sensor – Consult Factory) 00-1045 Acetic acid CH3COOH, 100/500 ppm 00-1704 Peracetic acid PAA Vapor, 1/5 ppm 00-1705 Peracetic acid PAA Vapor, 10/100 ppm 00-1883 IR CH4, 0-20/100% LEL ** 00-1886 IR CO2, 0-0.2/1.5% |

** 00-1883 LEL CH4 sensor also responds to many other hydrocarbons. Response to other hydrocarbons is not 1:1 with CH4. Contact us for k factor data.

Receiver Module |

|

| Construction Display: | 4 digit LED, sunlight readable |

| Input: | Digital signal, 2 wire connection to remote sensor/transmitter |

| Output: | Isolated 4-20 mA DC, 1000 ohms maximum load |

| Alarms: | Two adjustable concentration alarms, set points adjustable from 5-100% of range |

| Alarm Indicators: | High intensity LED bars for WARNING (low set- point) and ALARM (high setpoint) |

| Indicator Function: | WARNING indicator non-latching, ALARM latching |

| Alarm Relays: | Three assignable alarm relays, 10 A, 120 VAC (5 A, 250 VAC) resistive Alarm relays assignable to either alarm set point |

| Relay Function: | Configurable for normal/fail-safe, latching/non- latching, and fast/slow operation |

| Relay & Indicator Reset: | Activated from front panel switch or through remote reset |

| Trouble Alarm: | Front panel LED indicator and SPDT, 10 A, 120 VAC (5A, 250 VAC) resistive relay; Relay factory set to fail-safe operation |

| Trouble Function: | Indicates loss of sensor/transmitter input or failure of sensor Auto-Test (if in use) |

| Gas Indicator: | LED bar on front panel with gas symbol overlay |

| Mounting: | Module mounts to 35 x 7.5 mm DIN rail |

| Electrical Connection: | Quick disconnect plug-in terminal blocks |

| Module Enclosure: | Noryl |

| Size: | 2.8″W x 3.6″L x 2.3″D (70 mm x 90 mm x 58 mm) |

| Operating Temperature: | -40° to +55°C |

| Humidity: | 0-99% non-condensing |

| Power: | 9-15 VDC, 300 mA maximum |

Module Enclosures |

|

| Single Module Enclosure: | NEMA 4X polystyrene, 4.33″W x 7.09″H x 4.33″D (110 x 180 x 110 mm) |

| Two Module Enclosure: | NEMA 4X polystyrene, 7.17″W x 7.09″H x 4.33″D (182 x 180 x 110 mm) |

| Three Module Enclosure: | NEMA 4X polystyrene, 10.0″W x 7.09″H x 4.33″D (254 x 180 x 110 mm) |

| Six Module Enclosure: | NEMA 4X polystyrene, 10.0″W x 14.21″H x 4.33″D (254 x 361 x 110 mm) |

Sensor/Transmitter |

|

| Measurement: | Gas type and range customer specified |

| Transmitter Type: | Two wire system, current pulse position signal |

| Sensor: | Electrochemical gas diffusion type (manufactured by ATI) |

| Accuracy: | Generally ±5% of value, but limited by available calibration of gas accuracy. |

| Zero Drift: | Sensor dependent but normally less than 2% per month, non-cumulative |

| Enclosure: | NEMA 4X polystyrene |

| Optional Enclosure: | Explosion-proof cast aluminum, Class I, Division I, Group B, C, & D |

| Electrical Connection: | Quick disconnect terminal blocks (two wires without polarity) |

| Connection Distance: | Up to 1000 feet (300 m) to receiver |

| Operating Temperature: | -25° to +55°C (-5° for oxygen) |

| Humidity: | 0-95% non-condensing |

| Option: | Sensor Auto-Test (available for most gases) |

| Size (Sensor Transmitter with Auto-Test): | 3.7″L x 6.5″W x 2.2″D (94 mm x 163 mm x 57 mm) |

| Power: | 12 VDC from receiver module |

Power Supply Module |

|

| Input Voltage: | 85-265 VAC, 50/60 Hz, or 85-265 VDC, self regulating |

| Output Voltage: | Regulated 13.7 VDC, 1A |

| Output Connection: | 3 separate connections, two for receiver modules, and one for external battery back-up |

| Alarm: | Loss of input power alarm relay, SPDT 10 A, 120 VAC (5A, 250 VAC) resistive |

| Operating Temperature: | -40° to +55°C |

| Humidity: | 0-99% non-condensing |

| Module Enclosure: | Noryl |

| Size: | 2.8″W x 3.6″L x 2.3″D (70mm x 90 mm x 58 mm) |

| Electrical Connection: | Quick disconnect terminal blocks |

| Mounting: | Module mounts to 35 x 7.5 mm DIN rail |

Battery Back-Up | |

| Battery: | 12 VDC, 4 Ampere hour |

| Charge Control: | Current limited to .75 A max. |

| Low Voltage Cutoff: | Relay disconnect at 10 VDC |

| Fault Protection: | Relay disconnect on shorted charger wiring |

| Enclosure: | NEMA 4X polystyrene |

| Size: | 4.33”W x 7.09”L x 3.54”D (110 mm x 180 mm x 90 mm) |

WJF Instrumentation Ltd.

#5 3610 – 29th Street N.E.

Calgary, Alberta

Canada

T1Y 5Z7

Calgary Head Office

Toll-Free: (877)291-5572

Standard: (403)291-5570

Ontario & Maritimes Sales:

(905)809-6918