Home > Gas Detection > Wet H2S Gas Detector

ATi’s Q45S Wet H2S gas detector is a new type of gas sensor technology that allows continuous monitoring of hydrogen sulfide in both inlet and discharge air, where condensing humidity conditions are normal.

Odour control in wastewater treatment plants and sewage collection systems often requires the use of scrubber systems. Many of these scrubbers employ a wet process using a hypochlorite solution to remove hydrogen sulfide (H2S) from air streams prior to discharge. Monitoring the hydrogen sulfide in both inlet and discharge air has presented problems for standard sulfide gas sensors.

Measurements may be either at the inlet to scrubber systems where gas concentrations can run as high as 200 PPM or at the outlet, where gas concentrations are ideally down below 0.5 PPM. Special gas sensor configurations are available for either duct insertion or flowcell use.

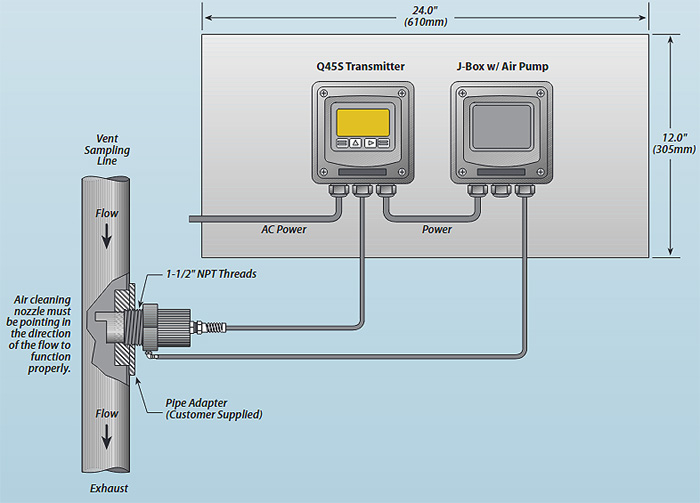

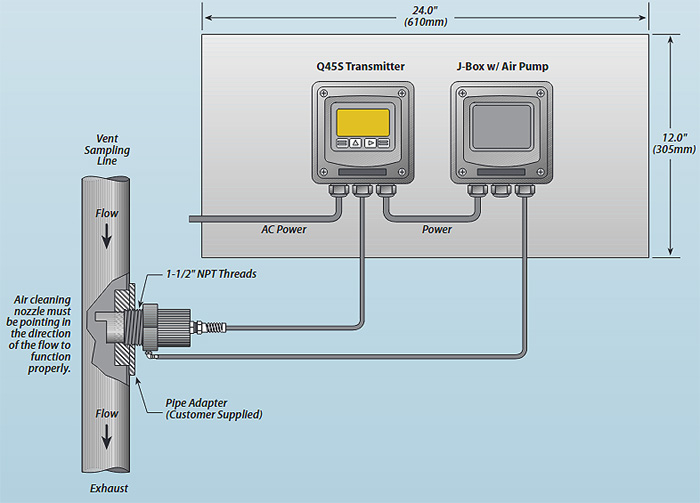

As Q45S Wet H2S Gas Detector systems are often monitoring gas streams with condensing levels of water vapor, provision has been made for eliminating water droplets from the gas sensor that could present a barrier to the diffusion of hydrogen sulfide into the sensor. An optional air-purge system controlled by the gas transmitter will periodically deliver a blast of air across the critical sensor surfaces to remove water droplets. This system insures a clear gas diffusion path to the sensor and reliable measurements on a continuous basis.

Designated Model Q45S, the odor monitoring system uses our standard Q45 electronics package in conjunction with a special “Wet H2S” sensor. Measurements may be made either at the inlet to scrubber systems where concentrations can run as high as 200 PPM, or at the outlet where concentrations are ideally down below 0.5 PPM. Special sensor configurations are available for either duct insertion or flowcell use.

Because Q45S systems are often monitoring gas streams with condensing levels of water vapor, provision has been made for eliminating water droplets from the sensor that could present a barrier to the diffusion of H2S into the sensor. An optional air-purge system controlled by the transmitter will periodically deliver a blast of air across the crititcal sensor surfaces to remove water droplets. This system insures a clear gas diffusion path to the sensor and reliable measurements on a continuous basis.

Q45S Wet H2S Gas Detector transmitters provide a large, easy to read LCD display of H2S concentration with a second display line to indicate other status information. An alarm contact is available for external alarming functions, and a second contact may be used for alarm purposes if the air purge system is not implemented in a given application. An isolated 4-20 mA output is provided for remote data transmission, and output spans are user programmable for ranges of 0-2.000 PPM up to 0-200.0 PPM.

A special battery-powered version of the Q45S Wet H2S Gas Detector is available for use in temporary installations. This system runs on an internal 9 volt battery and contains a data-logger for collecting information on existing air collection systems. A standard 9 volt battery will operate the unit for 4 days, while a 9 volt lithium battery will provide about 10 days of operation. Data is easily downloaded to a standard PC using software supplied with the unit.

Model Q45S |

– |

A |

– |

B |

– |

Wet Hydrogen Sulfide Monitor |

| Gas Type: | Hydrogen Sulfide |

| Sensor Type: | Special wet gas sensor design |

| Display: | 0-2.000 PPM, 0-20.00 PPM, 0-200.0 PPM (programmable) |

| Response Time: | 90% in 60 seconds |

| Accuracy: | Generally ±10% of value, but limited by available calibration gas |

| Sensitivity: | 0.1 PPM minimum |

| Zero Stability: | ± 0.04 PPM |

| Electronic Linearity: | ±0.5% |

| Span Drift: | Dependent on operating environment but generally less than 3% per month |

| Analog Output: | Isolated 4-20 mA, 575 ohms maximum |

| Power: | 115 or 230 VAC, 50/60 Hz., 5 VA max. Optional: 9 VDC battery-powered with data logger |

| Alarm Relays: | Two SPDT, 5 A @ 230 VAC resistive |

| Relay Coil: | Programmable either normally energized or normally de-energized |

| Enclosure: | Nema 4X Polycarbonate, Wall, pipe, or panel mounted |

| Controls: | 4 membrane switches on front of monitor. |

| Operating Temperature: | -20º to +50º C |

| Operating Pressure: | -0.2 to 10 PSIG |

| Weight: | 4 Lbs (1.8 Kg.) |

ATi’s Q45S Wet H2S gas detector is a new type of gas sensor technology that allows continuous monitoring of hydrogen sulfide in both inlet and discharge air, where condensing humidity conditions are normal.

Odour control in wastewater treatment plants and sewage collection systems often requires the use of scrubber systems. Many of these scrubbers employ a wet process using a hypochlorite solution to remove hydrogen sulfide (H2S) from air streams prior to discharge. Monitoring the hydrogen sulfide in both inlet and discharge air has presented problems for standard sulfide gas sensors.

Measurements may be either at the inlet to scrubber systems where gas concentrations can run as high as 200 PPM or at the outlet, where gas concentrations are ideally down below 0.5 PPM. Special gas sensor configurations are available for either duct insertion or flowcell use.

As Q45S Wet H2S Gas Detector systems are often monitoring gas streams with condensing levels of water vapor, provision has been made for eliminating water droplets from the gas sensor that could present a barrier to the diffusion of hydrogen sulfide into the sensor. An optional air-purge system controlled by the gas transmitter will periodically deliver a blast of air across the critical sensor surfaces to remove water droplets. This system insures a clear gas diffusion path to the sensor and reliable measurements on a continuous basis.

Designated Model Q45S, the odor monitoring system uses our standard Q45 electronics package in conjunction with a special “Wet H2S” sensor. Measurements may be made either at the inlet to scrubber systems where concentrations can run as high as 200 PPM, or at the outlet where concentrations are ideally down below 0.5 PPM. Special sensor configurations are available for either duct insertion or flowcell use.

Because Q45S systems are often monitoring gas streams with condensing levels of water vapor, provision has been made for eliminating water droplets from the sensor that could present a barrier to the diffusion of H2S into the sensor. An optional air-purge system controlled by the transmitter will periodically deliver a blast of air across the crititcal sensor surfaces to remove water droplets. This system insures a clear gas diffusion path to the sensor and reliable measurements on a continuous basis.

Q45S Wet H2S Gas Detector transmitters provide a large, easy to read LCD display of H2S concentration with a second display line to indicate other status information. An alarm contact is available for external alarming functions, and a second contact may be used for alarm purposes if the air purge system is not implemented in a given application. An isolated 4-20 mA output is provided for remote data transmission, and output spans are user programmable for ranges of 0-2.000 PPM up to 0-200.0 PPM.

A special battery-powered version of the Q45S Wet H2S Gas Detector is available for use in temporary installations. This system runs on an internal 9 volt battery and contains a data-logger for collecting information on existing air collection systems. A standard 9 volt battery will operate the unit for 4 days, while a 9 volt lithium battery will provide about 10 days of operation. Data is easily downloaded to a standard PC using software supplied with the unit.

Model Q45S |

– |

A |

– |

B |

– |

Wet Hydrogen Sulfide Monitor |

| Gas Type: | Hydrogen Sulfide |

| Sensor Type: | Special wet gas sensor design |

| Display: | 0-2.000 PPM, 0-20.00 PPM, 0-200.0 PPM (programmable) |

| Response Time: | 90% in 60 seconds |

| Accuracy: | Generally ±10% of value, but limited by available calibration gas |

| Sensitivity: | 0.1 PPM minimum |

| Zero Stability: | ± 0.04 PPM |

| Electronic Linearity: | ±0.5% |

| Span Drift: | Dependent on operating environment but generally less than 3% per month |

| Analog Output: | Isolated 4-20 mA, 575 ohms maximum |

| Power: | 115 or 230 VAC, 50/60 Hz., 5 VA max. Optional: 9 VDC battery-powered with data logger |

| Alarm Relays: | Two SPDT, 5 A @ 230 VAC resistive |

| Relay Coil: | Programmable either normally energized or normally de-energized |

| Enclosure: | Nema 4X Polycarbonate, Wall, pipe, or panel mounted |

| Controls: | 4 membrane switches on front of monitor. |

| Operating Temperature: | -20º to +50º C |

| Operating Pressure: | -0.2 to 10 PSIG |

| Weight: | 4 Lbs (1.8 Kg.) |

WJF Instrumentation Ltd.

#5 3610 – 29th Street N.E.

Calgary, Alberta

Canada

T1Y 5Z7

Calgary Head Office

Toll-Free: (877)291-5572

Standard: (403)291-5570

Ontario & Maritimes Sales:

(905)809-6918