Home > Walchem Canada > Water Treatment Metering Pump / Chemical Feed Pump

The EHE is the workhorse of the E-Class metering pumps. EHE Series pumps have outputs up to 20 GPH (75 l/h) and pressure capabilities to 150 PSI (10 bar).

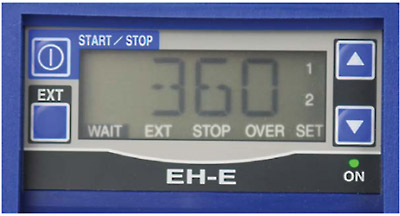

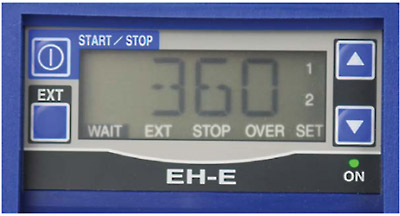

Combining the EHE performance with a turndown ratio of 1800:1 yields one of the most versatile pumps in the water treatment industry today. Superior mechanical design and quality of manufacturing merge to create a pump better than the sum of its parts. The versatile control features enable the EHE to be inte-grated into virtually any chemical feed application. The 360 stroke-per-minute operation results in high-resolution chemical feed and long service life. EHE pumps prime in seconds and hold prime reliably.

A pump’s maximum pressure rating times its maximum output at that pressure gives a relative measure of the pump’s hydraulic output power, a “power index.” The EHE36, with an output of 8.5 GPH at 105 PSI, yields a power index of 892.5. No other electronic metering pump in this range even comes close!

The EHE series does its work extremely well. Hydraulic output is maximized by its economical use of electricity via excellent heat rejection, valves that positively and consistently seat and unique front-and-back support of the armature.

Superior magnetic, electronic, thermal and hydraulic designs have been achieved in the EHE metering pump. The result is a pump that will perform longer at maximum duty than any other comparable pump.

| EH | E36 | E | 1 | PC | V |

| Pump Series | Capacity/ Pressure | Control Module | Voltage | Liquid End | Options |

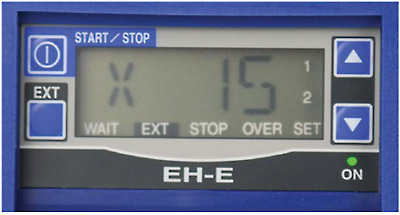

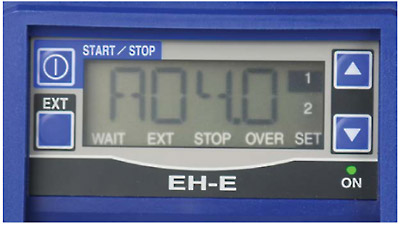

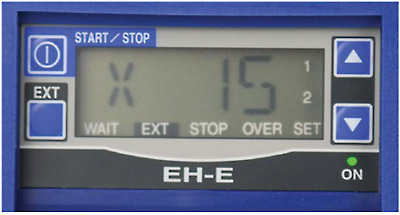

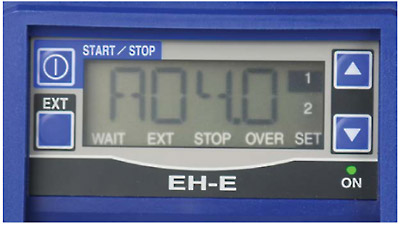

EH = Microprocessor control for all EHE models. Features manual speed control from 1 to 360 spm in 1 spm increments. External control from pulse signal with internal multiply and divide or from analog 4-20 mA signal.

See chart on this page

E = For use on all EHE models, features external pulse capability. (pulse divide, pulse multiply, analog)

1 = 115VAC, 50/60 Hz

2 = 230VAC, 50/60 Hz

LIQUID END

See chart on this page

Blank = 1/2” O.D. tube connection and standard accessories.

(HV is 1/2” O.D. discharge x 1/2” I.D. suction)

V = Standard 1/2” tube connections with back

pressure/anti-syphon valve added. (Not available on

FC models)

T = 3/4” NPT (male) pipe thread connection. (1/2”

MNPT on HV pumps). No MAVV.

P = 3/4” NPT (male) connection (1/2” MNPT on HV

pumps) with back pressure/anti-syphon valve. (No

MAVV.

Note: NPT piping connection material of construction will be

the same as the liquid end.

All pumps include a manual air vent valve with the exception

of FC/HV liquid ends and options P and T.

All pumps include one foot valve, one injection valve,

20 feet of polyethylene tubing and one ceramic weight

with the exception of HV models (tubing only) and options

P and T.

CE Alumina ceramic

EPDM Ethylene propylene diene monomer

FKM Fluoroelastomer

GFRPP Glass fiber reinforced polypropylene

PE Polyethylene

PTFE Polytetrafluoroethylene

PCTFE Polychlorotrifluoroethylene

PVC Polyvinylchloride (translucent)

PVDF Polyvinylidenefluoride

HC Hastelloy C276

The EHE is the workhorse of the E-Class metering pumps. EHE Series pumps have outputs up to 20 GPH (75 l/h) and pressure capabilities to 150 PSI (10 bar).

Combining the EHE performance with a turndown ratio of 1800:1 yields one of the most versatile pumps in the water treatment industry today. Superior mechanical design and quality of manufacturing merge to create a pump better than the sum of its parts. The versatile control features enable the EHE to be inte-grated into virtually any chemical feed application. The 360 stroke-per-minute operation results in high-resolution chemical feed and long service life. EHE pumps prime in seconds and hold prime reliably.

A pump’s maximum pressure rating times its maximum output at that pressure gives a relative measure of the pump’s hydraulic output power, a “power index.” The EHE36, with an output of 8.5 GPH at 105 PSI, yields a power index of 892.5. No other electronic metering pump in this range even comes close!

The EHE series does its work extremely well. Hydraulic output is maximized by its economical use of electricity via excellent heat rejection, valves that positively and consistently seat and unique front-and-back support of the armature.

Superior magnetic, electronic, thermal and hydraulic designs have been achieved in the EHE metering pump. The result is a pump that will perform longer at maximum duty than any other comparable pump.

| EH | E36 | E | 1 | PC | V |

| Pump Series | Capacity/ Pressure | Control Module | Voltage | Liquid End | Options |

EH = Microprocessor control for all EHE models. Features manual speed control from 1 to 360 spm in 1 spm increments. External control from pulse signal with internal multiply and divide or from analog 4-20 mA signal.

See chart on this page

E = For use on all EHE models, features external pulse capability. (pulse divide, pulse multiply, analog)

1 = 115VAC, 50/60 Hz

2 = 230VAC, 50/60 Hz

LIQUID END

See chart on this page

Blank = 1/2” O.D. tube connection and standard accessories.

(HV is 1/2” O.D. discharge x 1/2” I.D. suction)

V = Standard 1/2” tube connections with back

pressure/anti-syphon valve added. (Not available on

FC models)

T = 3/4” NPT (male) pipe thread connection. (1/2”

MNPT on HV pumps). No MAVV.

P = 3/4” NPT (male) connection (1/2” MNPT on HV

pumps) with back pressure/anti-syphon valve. (No

MAVV.

Note: NPT piping connection material of construction will be

the same as the liquid end.

All pumps include a manual air vent valve with the exception

of FC/HV liquid ends and options P and T.

All pumps include one foot valve, one injection valve,

20 feet of polyethylene tubing and one ceramic weight

with the exception of HV models (tubing only) and options

P and T.

CE Alumina ceramic

EPDM Ethylene propylene diene monomer

FKM Fluoroelastomer

GFRPP Glass fiber reinforced polypropylene

PE Polyethylene

PTFE Polytetrafluoroethylene

PCTFE Polychlorotrifluoroethylene

PVC Polyvinylchloride (translucent)

PVDF Polyvinylidenefluoride

HC Hastelloy C276

WJF Instrumentation Ltd.

#5 3610 – 29th Street N.E.

Calgary, Alberta

Canada

T1Y 5Z7

Calgary Head Office

Toll-Free: (877)291-5572

Standard: (403)291-5570

Ontario & Maritimes Sales:

(905)809-6918