We stock a large selection of Solenoid Valves available for shipping from our location in Calgary, Alberta, Canada. Below is a small selection of more popular valves.

Contact us for advice and consultation regarding valve configuration and our expert staff can help you.

Solenoid valves are electromechanical devices used in fluid control applications. Typically used in industry for fluids such as water, air, gas and oil. Most solenoid valves are actuated electrically and are composed of a coil that creates a magnetic field to push or pull an armature connected to the main valve mechanism.

- Type 6213 - 2/2-way Solenoid Valves for Fluids - Compact High Flow Body

- Type 5282 - 2/2-way Solenoid Valves with Servo Diaphragm.

- Type 0142 - 2/2-way Solenoid Valves for Aggressive and Contaminated Media.

- Type 6014 - Plunger Valve 3/2 way Direct-Acting Solenoid Valves.

- D-LUX Timer - Digital Electronic Solenoid Valve Timer

- Type 8644 - Remote Process Actuation Control System AirLINE - Rockwell 1734 Point I/O System.

- Type 8640 - Modular Pneumatic Valve Unit.

- Direct Acting Solenoid Valve 2/2 way - Plunger Type 256

- Burkert 6013 Solenoid Valve Plunger Type 2/2 way Direct Acting

- Hazardous Area Classification Servo-Assisted 2/2 way Diaphragm Valve - Burkert Type 290

- 2/2 Way Diaphragm Valve - Explosion Proof & Standard (Servo-assisted) Burkert type 6281

Type 6213 – 2/2-way Solenoid Valves for Fluids – Compact Body.

The Type 6213 is a 2/2–way normally closed solenoid valve with a forced coupled diaphragm system. It switches from 1.5 PSI and can be used universally for fluids. For complete opening, a differential pressure of at least 1.5 PSI is necessary

- Compact body with high flow rate.

- 1/4″ NPT up to 2″ NPT Sizes

- Brass or 316 stainless steel body.

- Direct acting, 0 to 140 PSI range.

- Cold or hot water.

- Optional LED indicators.

- Push-over coil.

- Waterhammer-free, low noise.

- Energy-saving double coil technology with kick and drop design

- Diaphragm materials:

- NBR

- EPDM

- FKM

The spring coupling of the diaphragm supports the opening process of the valve.

In its standard version, the valve is suitable for use in liquids. A minimum differential pressure is required for complete opening. A special version (HP00) which opens the valve without differential pressure is available for gas and vacuum applications.

Various diaphragm material combinations are available depending on the application.

The standard brass housing satisfies all European drinking water requirements. Dezincification-resistant brass is available for other markets.

The housing offering is rounded off with a stainless steel version. To reduce power consumption in operation, coils with “Kick and Drop” (KD) electronics (double coil technology) are available.

In combination with a plug in accordance with DIN EN 175301-803 Form A, the valves satisfy protection class IP65 – in combination with a stainless steel housing NEMA 4X.

Call 1-877 291 5572 for valve consultation and configuration questions.

Type 5282 – 2/2-way Solenoid Valves with Servo Diaphragm.

The Type 5282 is a pilot-controlled normally closed solenoid valve with a servo-diaphragm, media separated, for universal use with liquid and gaseous media corresponding to the material resistance.As standard, the 3-way pivoted armature pilot drive has an emergency manual operation. The closing and opening times are continuously adjustable.

- Pivoted armature pilot drive with emergency manual operation.

- Media separated.

- Circuit function can be modified.

- Adjustable switching times (waterhammer-free).

- Good for more aggressive media.

- 1/2″ NPT to 2″ NPT sizes.

- Brass or 316 Stainless steel body.

- 2.8 to 140 PSI range.

- Optional LED indicators.

- Diaphragm materials:

- NBR

- EPDM

- FKM

The 5282 valve is a servo-assisted diaphragm valve. A minimum differential pressure is required for the valve to function.

Various diaphragm material combinations and circuit functions are available depending on the application.

The standard brass body satisfies all European drinking water requirements.

The body offering is completed with stainless steel versions.

The 3/2-way pilot valve can be easily converted from NC to NO circuit function by rotating it on the armature.

The solenoid coils are molded with a chemically resistant epoxy.

The 5282 is equipped with manual override for start-up and testing. In combination with a plug acc. to DIN EN 175301-803 Form A and stainless steel body, the valves satisfy the requirements of NEMA 4X.

Call 1-877 291 5572 for valve consultation and configuration questions.

Type 142 – 2/2-way Solenoid Valves for Aggressive and Contaminated Media.

Servo-assisted solenoid valve with diaphragm, normally closed function. Hermetic isolation of fluid from the actuator. A minimum differential pressure of 7 PSI is required to fully open the valve. Valves can be mounted or removed radially for a space-saving installation.

- 20mm up to 63mm sizes.

- PVC or PVDF Body. Non-metallic valve internals.

- Isolating diaphragm between the solenoid and fluid

- Adjustable switching times (waterhammer-free).

- For aggressive media.

- Pivoted armature, with lockable manual override.

- Diaphragm materials:

- EPDM

- FKM

The 0142 valve is a servo-assisted diaphragm valve. A minimum differential pressure of 0.5 bar is required to open and close the valve.

Various diaphragm material combinations and methods of operation are available depending on the application. The 3/2 way pilot valve can be easily converted from NC to NO functioning principle by rotating it on the main seat. The pilot valve position feedback can take place with a switching or NAMUR signal.

The solenoid coils are molded with a chemically resistant epoxy.

The 0142 is equipped with manual override for commissioning and testing.

To reduce power consumption in operation, coils with “Kick and Drop” (KD) electronics (double coil technology) are available.

In combination with a cable plug in accordance with DIN EN 175301 – 803 Form A, the valves satisfy protection class IP65 and NEMA 4X.

Call 1-877 291 5572 for valve consultation and configuration questions.

Type 6014 – Plunger Valve 3/2 way Direct-Acting Solenoid Valves.

Direct–acting Type 6014 valve for individual or manifold mounting with push–over coil, for use with a variety media depending on the materials of construction. Delivered in various body materials and also suitable for use in technical vacuum

- Direct-acting, compact valve.

- Vibration-proof, bolted coil system.

- Service-friendly manual override.

- Energy-saving pulse versions.

- 3-way, 1/4″ NPT Piloting Solenoid Valve.

- Brass or 316 Stainless Steel Body.

- For piloting air-actuated on/off valves.

- Banjo (direct-mount) versions available.

- Diaphragm materials:

- EPDM

- FKM

Valve 6014 is a direct-acting plunger valve. The stopper and plunger guide tube are welded together to enhance pressure resistance and leak-tightness.

Various seal material combinations are available depending on the application.

A Bürkert-specific flange design (SFB) enables space-saving arrangement of valves on a manifold.

The coils are molded with polyamide or with chemically resistant epoxy.

Pulse coils are available for the reduction of electrical power consumption during operation.

Optional manual actuation enables quick commissioning and easy maintenance.

In combination with a plug in accordance with DIN EN 175301-803 Form A, the valves satisfy protection class IP65. Stainless steel valves satisfy NEMA 4X.

Call 1-877 291 5572 for valve consultation and configuration questions.

D-LUX Timer – Digital Electronic Solenoid Valve Timer

The D-LUX Timer is produced using SMT (Surface Mounting Technology), ensuring improved performance and consistency.

The unit offers the luxury of true digital time cycle programming and the cycle options are enormous. In addition, there are four cycle types, making this the most flexible and easy to use solenoid valve timer – suitable for a whole range of applications.

The D-LUX Timer is designed to fit all solenoid valves with connection type DIN 43650 – A/ISO 4400.

- Use with most Bürkert Valves.

- Ideal for the automatic draining of compressed air systems.

- Plug-on programmable timer.

- 0.1 Seconds to 99 Hours (both ON and OFF).

- NEMA4 (IP65).

Call 1-877 291 5572 for valve consultation and configuration questions.

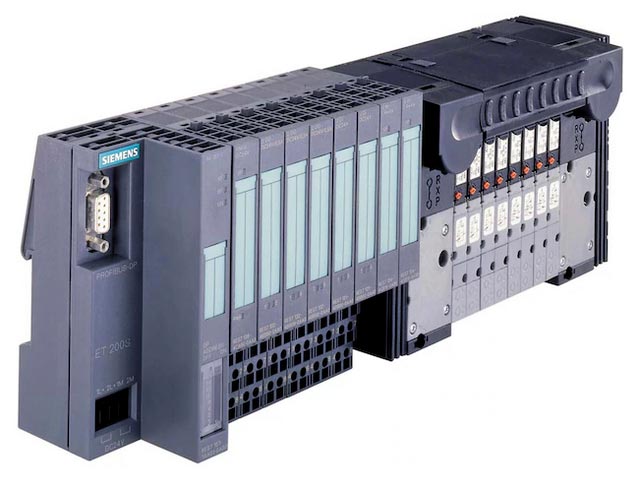

Type 8644 – Remote Process Actuation Control System AirLINE – Rockwell 1734 Point I/O System.

The AirLINE System integrates high performance solenoid pilot valves, remote electronic I/O and fieldbus communication into a process actuation and control system that is both compact and extremely flexible. Its modular design allows fully customized, pre-mounted and tested solutions to exactly meet all application needs including the integration of a local Mini PLC. Due to the full electronic and mechanical integration, the valve block can be added without the need of any tools or wiring.

- Fully compatible with Rockwell 1734 Point I/O System.

- Combination of Fieldbus, Analog pilot valves and I/O modules.

- Innovative fieldbus interface.

- High flexibility.

- Compact design.

- High flow rate.

Valve Configuration Software

AirLine is a system of modular design which is precisely adapted to the specific requirements of the customer. A software program, the “Configurator”, for the simple, precise generation of the required configuration of each Airline system.

The Burkert Configurator defines:

- Number and types of valves

- Type of (intermediate) supplies

The results supplied by the

Configurator:

- Bill of materials, incl. list prices

- Illustration.

Call 1-877 291 5572 for valve consultation and configuration questions.

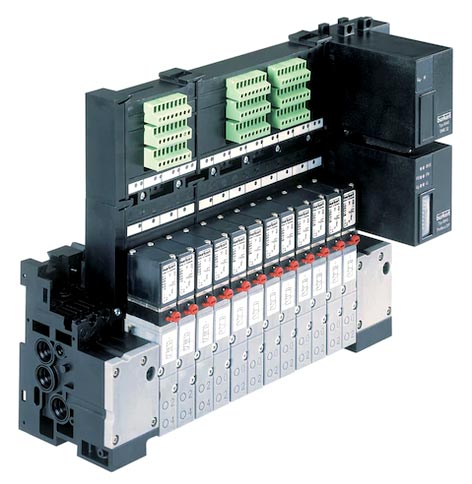

Type 8640 – Modular Pneumatic Valve Unit.

The 8640 valve unit system is designed to solve diverse and complex control problems due to its systematic modular construction and combination of pneumatic and electrical interfaces.By putting together a row of pneumatic modules with different numbers of valves, 2 to 24 valve functionalities may be realized on one valve unit.

- Modular system with multiple valves.

- Compact, easy to connect systems.

- High flow rates, highly reliable.

- Available with analog and digital I/O

- High flexibility

- Simple exchange of valves (with option “P-shut-off”- also possible during operation).

Electrical connectivity is achieved by either fieldbus interfaces, common connection (parallel connection technique) or multipole interfaces.The valves allow different applications to be covered. Bodies and connection modules are made of high-quality plastic(polyamide) and are easy to assemble by means of the built-in snap connectors.

640 valve island system is a system of modular design which can be built up to specific requirements. Software program, the simple, precise generation of the required configuration of each 8640 system.

The Bürkert Configurator defines:

- Number and types of valves.

- Type of (intermediate) supplies.

- Combination of Fieldbus, pilot valves and I/O modules.

The results supplied by the Configurator:

- Bill of materials.

- Illustration.

- Drawings.

Call 1-877 291 5572 for valve consultation and configuration questions.

How does a Solenoid Valve Work?

The three fundamental parts of a solenoid valve are the coil, armature, and valve body. The coil, an electromagnet, draws the armature into a magnetic field when it is activated, opening or closing the valve as a result. The valve opens or shuts when the magnetic field draws the armature, which is connected to the valve stem. The valve body houses every component and is designed to endure a range of temperatures, pressures, and corrosive substances depending on the application.

Two-way, three-way, and four-way valves are the most prevalent industrial solenoid valves, and each has a specific design that is suited to it’s application. A 2-way solenoid valve is made for simple on/off control. The valve is opened when the coil is activated, and it is closed when the coil is de-powered. An additional port on a 3-way solenoid valve allows it to switch between two separate routes. Comparably, four separate pathways can be switched using a four-way solenoid valve.

Solenoid valves are employed in a variety of industrial settings, including air conditioning systems, oil and gas pipelines, chemical processing facilities, medical equipment, and automotive systems. Due to their versatility in being easily altered to meet various requirements, they are utilized throughout many industries.

Over other types of valves, solenoid valves provide a number of advantages. Compact, dependable, and rather simple to install and maintain, they are. They also have a high level of effectiveness and efficiency. The ability to control the flow of fluids is further improved by their quick response times.