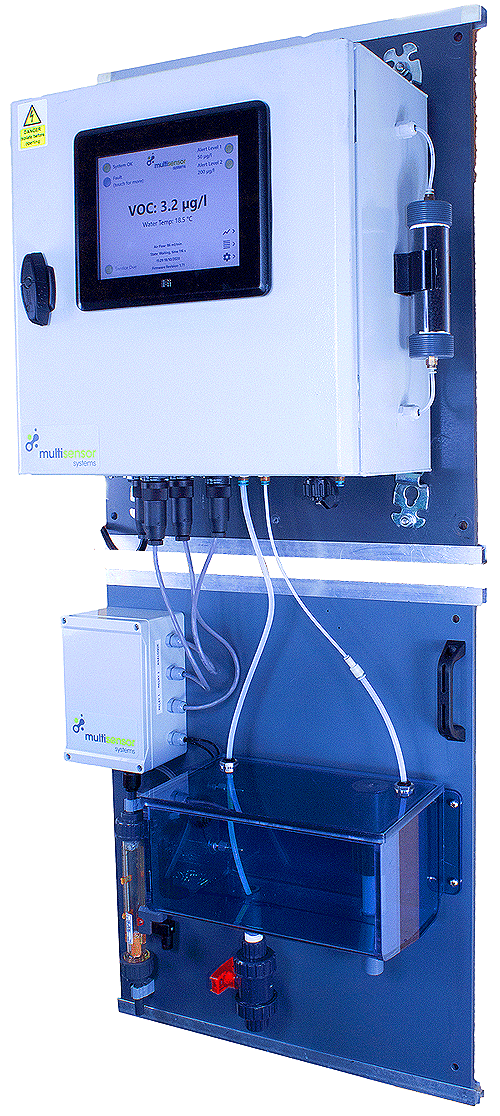

The Multisensor oil in water Monitoring System simplifies low-level (ppb) hydrocarbon/VOC monitoring.

When oil is present in water, minute concentrations of VOC/hydrocarbons can be detected. Applications include; raw river water, reservoir/surface water, potable water, effluent water and wastewater.

Some other applications include RO membrane and carbon bed protection, and VOCs in process water.

Utilizing a proprietary “electronic nose” sensor, the MS1200 system detects VOCs using gas phase analysis. This means that the sensor system does not actually touch the water itself. This allows for many months of trouble-free operation at a time.

The MS1200 oil in water monitor can operate in the range of 0-3000 ppb, monitoring for both aliphatic chains and aromatic rings. This makes it a both a versatile and a sensitive tool for plant and environmental protection without the hassles and costs of more complicated monitoring system such as GC (gas chromatography), mass spectrometry, or fluorescence type systems.

| Range* | 0 – 3000 ppb in water |

| Accuracy** | +/-10% |

| Repeatability | +/-2% |

| Sampling Frequency | Continuous Mode / 20 Minutes Mode |

| User Interface | 8″ resistive touchscreen (optional) |

| Data Storage | µSD Card and Internal Memory |

| Data Interface | 4 – 20 mA and USB (Standard); Profibus, Modbus, Wireless (Optional) |

| Alarms | x2 Via Relay Drivers, Levels User Definable |

| Operating Temperature | Range 0 °C– 40 °C (contact us for wider temperature range) |

| Water Temperature Range | 1 °C– 40 °C |

| Power Consumption | Standard Version: 10 W Continuous (90-240 VAC or 24 VDC) |

| Touchscreen | Version: 20 W Continuous (90-240 VAC or 24 VDC) |

| ATEX | Zone 2 (Optional) |

| Reagents | None |

| Carrier Gas | None |

| Consumables | GAC filter media, Air Filter every 6 months |

| Validation | Every 6 Months |

Oil in water Monitoring System, to protect water intake and the potential damage to water systems. A low level alarm at around 20 ppb and a high level alarm at 50 – 100 ppb Will enable the operator to take early and meaningful action, to isolate and protect water security.

Used in any situation where water security is vital to protect systems or communities from contamination.

Protection in any situation where the potential for oils and hydrocarbons to enter the supply water used in potable and sanitary applications.

Hydrocarbons are, very often, the main component of a wide range of products. From fuels to solvents to many of the chemicals used in industry during their treatment processes.

Agricultural fuel storage can result in accidental spills into water courses and aquifers.

Monitoring of hydrocarbon leaks in cooling water

The presence of hydrocarbons, (oil in water) indicates a loss of product, reduced heat exchange capability and the possibility for dangerous hydrocarbon build ups.

Regulations are getting stricter and stricter, which means that more and more companies are required to monitor and control their effluent.

A basic form of control focuses on the measurement of flow, pH and DO.

Basic measurements like pH and DO are common, some applications may require TOC, BOD or COD. Oil in water, VOC analyzers fill the gap to detect many different kinds of hydrocarbons as listed in the table below.

Industrial Source | VOC |

| Petrol, diesel, fuel oil, paint thinners, oil based stains and paints, insecticides, mineral spirits and furniture polishes. | BTX(Benzene, Toulene, Ethyl benzene, Xylene), Hexane, Cyclohexane and Trimethylbenzene. |

| Nail polish remover, colognes, perfumes, rubbing alcohol, hair spray. | Acetone, Ethyl Alcohol, Isopropyl Alcohol, Methacrylates, Ethyl Acetate |

| Dry cleaning liquid, spot removers, fabric/leather cleaners | Tetrachlorethene(PERC) and Trichloroethene(TEC) |

| Citrus (orange) oil or pine oil cleaners, solvents and some odour masking products. | d-limonene (citrus odour), a-pinene (pine odour), isoprene |

| PVC cement and primer, various adhesives, contact cement, model cement | Tetrahydrofuran, Cyclohexane, Methyl ethyl ketone(MEK), Toulene, Acetone, Hexane, 1,1,1-Trichloroethane, Methyl-iso-butyl ketone (MIBK) |

| Paint stripper, adhesive (glue) removers | Methylene chloride, Toulene, older products may contain Carbon Tetrachloride |

| Degreasers, aerosol penetrating oils, break cleaner, carburetor cleaner, commercial solvents, electronics cleaners, spray lubricants | Methylene chloride, PERC, TCE, Toulene, Xylenes, Methyl ethyl ketone, 1,1,1-Trichloroethane |

| Moth balls, moth flakes, deodorizers, air fresheners | 1,4-Dichlorobenzene, Naphthalene |

| Refrigerant from air conditioners, freezers, refrigerators, dehumidifiers | Freon (Trichlorofluoromethane, Dichlorodifluoromethane) |

| Aerosol spray products for some paints, cosmetics, automotive products, leather treatment, pesticides | Heptane, Butane, Pentane |

| Upholstered furniture, carpets, plywood, pressed wood | Formaldehyde |

MS1200 utilises a contactless measurement, sensing headspace gases or volatiles in the sampling tank.

A system with very low maintenance, the sensor never touches the water. Resulting in reduced drift and virtually no fouling.

Accurate even in low ppb concentrations. A wide dynamic range allows application in a wide variety of environments.

All Swan Analyzers are CSA Cirtified at our premises before shipping.

120 L/h

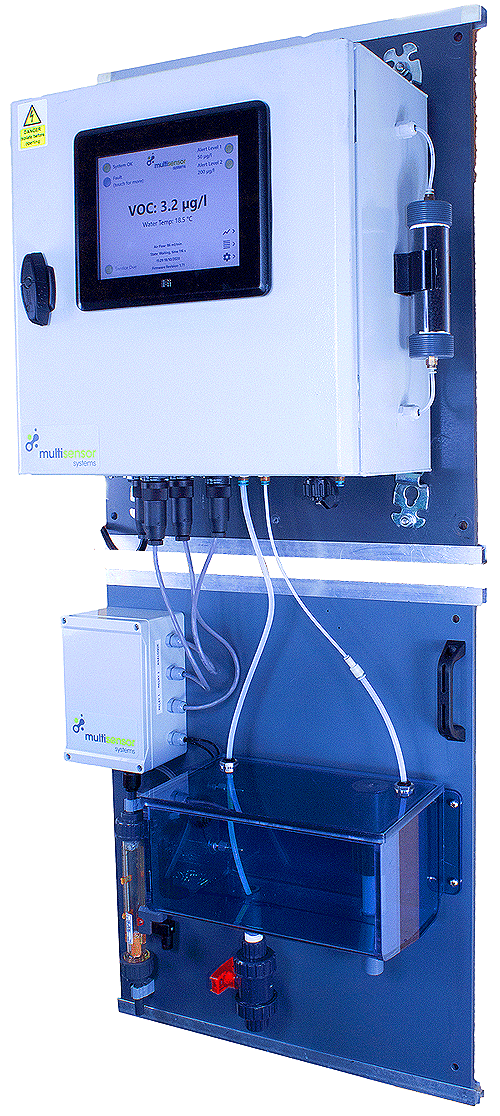

The Multisensor oil in water Monitoring System simplifies low-level (ppb) hydrocarbon/VOC monitoring.

When oil is present in water, minute concentrations of VOC/hydrocarbons can be detected. Applications include; raw river water, reservoir/surface water, potable water, effluent water and wastewater.

Some other applications include RO membrane and carbon bed protection, and VOCs in process water.

Utilizing a proprietary “electronic nose” sensor, the MS1200 system detects VOCs using gas phase analysis. This means that the sensor system does not actually touch the water itself. This allows for many months of trouble-free operation at a time.

The MS1200 oil in water monitor can operate in the range of 0-3000 ppb, monitoring for both aliphatic chains and aromatic rings. This makes it a both a versatile and a sensitive tool for plant and environmental protection without the hassles and costs of more complicated monitoring system such as GC (gas chromatography), mass spectrometry, or fluorescence type systems.

| Range* | 0 – 3000 ppb in water |

| Accuracy** | +/-10% |

| Repeatability | +/-2% |

| Sampling Frequency | Continuous Mode / 20 Minutes Mode |

| User Interface | 8″ resistive touchscreen (optional) |

| Data Storage | µSD Card and Internal Memory |

| Data Interface | 4 – 20 mA and USB (Standard); Profibus, Modbus, Wireless (Optional) |

| Alarms | x2 Via Relay Drivers, Levels User Definable |

| Operating Temperature | Range 0 °C– 40 °C (contact us for wider temperature range) |

| Water Temperature Range | 1 °C– 40 °C |

| Power Consumption | Standard Version: 10 W Continuous (90-240 VAC or 24 VDC) |

| Touchscreen | Version: 20 W Continuous (90-240 VAC or 24 VDC) |

| ATEX | Zone 2 (Optional) |

| Reagents | None |

| Carrier Gas | None |

| Consumables | GAC filter media, Air Filter every 6 months |

| Validation | Every 6 Months |

Oil in water Monitoring System, to protect water intake and the potential damage to water systems. A low level alarm at around 20 ppb and a high level alarm at 50 – 100 ppb Will enable the operator to take early and meaningful action, to isolate and protect water security.

Used in any situation where water security is vital to protect systems or communities from contamination.

Protection in any situation where the potential for oils and hydrocarbons to enter the supply water used in potable and sanitary applications.

Hydrocarbons are, very often, the main component of a wide range of products. From fuels to solvents to many of the chemicals used in industry during their treatment processes.

Agricultural fuel storage can result in accidental spills into water courses and aquifers.

Monitoring of hydrocarbon leaks in cooling water

The presence of hydrocarbons, (oil in water) indicates a loss of product, reduced heat exchange capability and the possibility for dangerous hydrocarbon build ups.

Regulations are getting stricter and stricter, which means that more and more companies are required to monitor and control their effluent.

A basic form of control focuses on the measurement of flow, pH and DO.

Basic measurements like pH and DO are common, some applications may require TOC, BOD or COD. Oil in water, VOC analyzers fill the gap to detect many different kinds of hydrocarbons as listed in the table below.

Industrial Source | VOC |

| Petrol, diesel, fuel oil, paint thinners, oil based stains and paints, insecticides, mineral spirits and furniture polishes. | BTX(Benzene, Toulene, Ethyl benzene, Xylene), Hexane, Cyclohexane and Trimethylbenzene. |

| Nail polish remover, colognes, perfumes, rubbing alcohol, hair spray. | Acetone, Ethyl Alcohol, Isopropyl Alcohol, Methacrylates, Ethyl Acetate |

| Dry cleaning liquid, spot removers, fabric/leather cleaners | Tetrachlorethene(PERC) and Trichloroethene(TEC) |

| Citrus (orange) oil or pine oil cleaners, solvents and some odour masking products. | d-limonene (citrus odour), a-pinene (pine odour), isoprene |

| PVC cement and primer, various adhesives, contact cement, model cement | Tetrahydrofuran, Cyclohexane, Methyl ethyl ketone(MEK), Toulene, Acetone, Hexane, 1,1,1-Trichloroethane, Methyl-iso-butyl ketone (MIBK) |

| Paint stripper, adhesive (glue) removers | Methylene chloride, Toulene, older products may contain Carbon Tetrachloride |

| Degreasers, aerosol penetrating oils, break cleaner, carburetor cleaner, commercial solvents, electronics cleaners, spray lubricants | Methylene chloride, PERC, TCE, Toulene, Xylenes, Methyl ethyl ketone, 1,1,1-Trichloroethane |

| Moth balls, moth flakes, deodorizers, air fresheners | 1,4-Dichlorobenzene, Naphthalene |

| Refrigerant from air conditioners, freezers, refrigerators, dehumidifiers | Freon (Trichlorofluoromethane, Dichlorodifluoromethane) |

| Aerosol spray products for some paints, cosmetics, automotive products, leather treatment, pesticides | Heptane, Butane, Pentane |

| Upholstered furniture, carpets, plywood, pressed wood | Formaldehyde |

MS1200 utilises a contactless measurement, sensing headspace gases or volatiles in the sampling tank.

A system with very low maintenance, the sensor never touches the water. Resulting in reduced drift and virtually no fouling.

Accurate even in low ppb concentrations. A wide dynamic range allows application in a wide variety of environments.

All Swan Analyzers are CSA Cirtified at our premises before shipping.

120 L/h

WJF Instrumentation Ltd.

#5 3610 – 29th Street N.E.

Calgary, Alberta

Canada

T1Y 5Z7

Calgary Head Office

Toll-Free: (877)291-5572

Standard: (403)291-5570

Ontario & Maritimes Sales:

(905)809-6918