Home > Temperature > Explosion Proof Pressure Transmitter

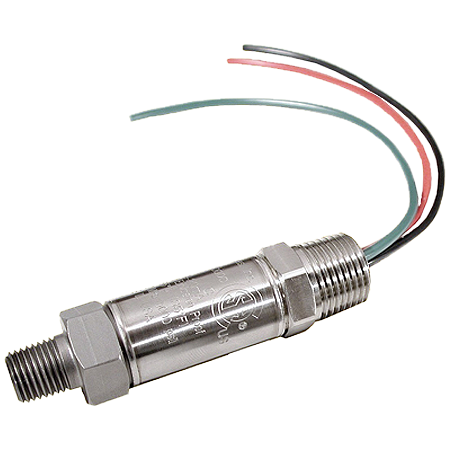

The explosion proof pressure transmitter is approved for use in hazardous locations per CSA Standard 30 and UL® Standard 1203 for Class 1, Division 1 and Division 2 hazardous locations.

Wetted parts are all 316L Stainless Steel (50 up to 10000 PSIG), 17-4PH (15000 & 20000 PSIG) for compatibility with a variety of media.

Wetted materials and construction comply with the NACE MR0175 Standard. The KP46’s fitting and sensing diaphragm are machined out of a single piece of material, so there are no welds, seams or O-ring seals, resulting in excellent long-term performance and stability.

The case is factory sealed, making this pressure transmitter very rugged with excellent shock and vibration resistance. The KP46 is perfect for explosion-proof applications where both price and performance are critical.

Order Details

| Range (PSIG) | Model Number | Range (PSIG) | Model Number | Range (PSIG) | Model Number |

| 0…50 | KP46-A00050P4W1 | 0…1000 | KP46-A01000P4W1 | 0…7500 | KP46-A07500P4W1 |

| 0…100 | KP46-A00100P4W1 | 0…1500 | KP46-A01500P4W1 | 0…10000 | KP46-A10000P4W1 |

| 0…200 | KP46-A00200P4W1 | 0…3000 | KP46-A03000P4W1 | 0…15000 | KP46-P15000P4W0 |

| 0…500 | KP46-A00500P4W1 | 0…5000 | KP46-A05000P4W1 | 0…20000 | KP46-P20000P4W0 |

| Pressure Range: | 0…50 PSIG to 0…20000 PSIG |

| Over Range Protection: | 2X full scale |

| Burst Pressure: | 5X full scale |

| Cycle Life: | >100 million cycles |

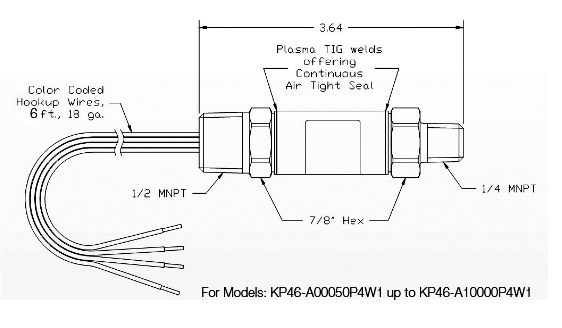

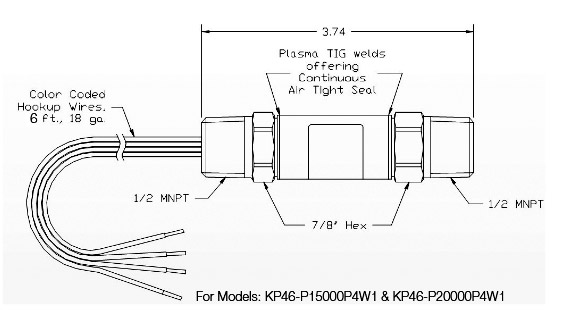

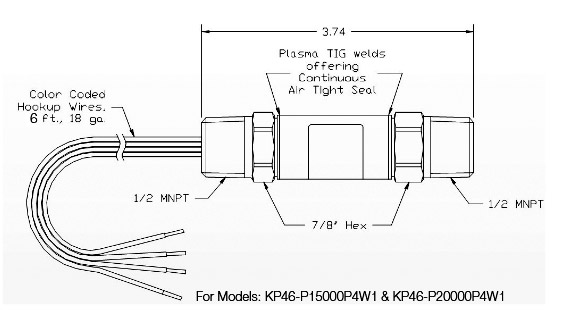

| Fitting Type: | 1/4″ NPT (up to 10000 PSIG) 1/2″ NPT (15000 & 20000 PSIG) |

| Wetted Materials: | 316L stainless steel (up to 10000 PSIG), 17-4PH stainless steel (15000 & 20000 PSIG), other materials upon request |

| Corrosion Resistance: | complies with NACE MR0175 |

| Accuracy: | ±0.25% BFSL |

| Zero Offset: | <±1% of full scale |

| Span Tolerance: | <±2% of full scale |

| Media Temp. Range: | -55…250 °F |

| Ambient Temp. Range: | -40…185 °F |

| Compensated Range: | 30…130 °F |

| Temperature Drift: | <±1.5% of full scale for zero and span over the compensated range |

| Shock Resistance: | 100G, 11mSec |

| Vibration Resistance: | 10G peak, 20-2000Hz |

| Stability (one year): | ±0.25% of full scale |

| Hazardous Location: | CSA approved to standards CSA 30 and U.L.1203; explosion-proof for Class 1, Div 1, Groups A, B, C, and D; and Div 2, Groups A, B, C, and D |

| Output: | 4…20 mA, 2-wire |

| Power Supply: | 10…28 VDC |

| Max. Loop Load: | 800Ω |

| Electrical Connection: | 1/2″ NPT conduit with 6 ft. wire leads |

| Electrical Protection: | NEMA 4X, IP 66 |

The explosion proof pressure transmitter is approved for use in hazardous locations per CSA Standard 30 and UL® Standard 1203 for Class 1, Division 1 and Division 2 hazardous locations.

Wetted parts are all 316L Stainless Steel (50 up to 10000 PSIG), 17-4PH (15000 & 20000 PSIG) for compatibility with a variety of media.

Wetted materials and construction comply with the NACE MR0175 Standard. The KP46’s fitting and sensing diaphragm are machined out of a single piece of material, so there are no welds, seams or O-ring seals, resulting in excellent long-term performance and stability.

The case is factory sealed, making this pressure transmitter very rugged with excellent shock and vibration resistance. The KP46 is perfect for explosion-proof applications where both price and performance are critical.

Order Details

| Range (PSIG) | Model Number | Range (PSIG) | Model Number | Range (PSIG) | Model Number |

| 0…50 | KP46-A00050P4W1 | 0…1000 | KP46-A01000P4W1 | 0…7500 | KP46-A07500P4W1 |

| 0…100 | KP46-A00100P4W1 | 0…1500 | KP46-A01500P4W1 | 0…10000 | KP46-A10000P4W1 |

| 0…200 | KP46-A00200P4W1 | 0…3000 | KP46-A03000P4W1 | 0…15000 | KP46-P15000P4W0 |

| 0…500 | KP46-A00500P4W1 | 0…5000 | KP46-A05000P4W1 | 0…20000 | KP46-P20000P4W0 |

| Pressure Range: | 0…50 PSIG to 0…20000 PSIG |

| Over Range Protection: | 2X full scale |

| Burst Pressure: | 5X full scale |

| Cycle Life: | >100 million cycles |

| Fitting Type: | 1/4″ NPT (up to 10000 PSIG) 1/2″ NPT (15000 & 20000 PSIG) |

| Wetted Materials: | 316L stainless steel (up to 10000 PSIG), 17-4PH stainless steel (15000 & 20000 PSIG), other materials upon request |

| Corrosion Resistance: | complies with NACE MR0175 |

| Accuracy: | ±0.25% BFSL |

| Zero Offset: | <±1% of full scale |

| Span Tolerance: | <±2% of full scale |

| Media Temp. Range: | -55…250 °F |

| Ambient Temp. Range: | -40…185 °F |

| Compensated Range: | 30…130 °F |

| Temperature Drift: | <±1.5% of full scale for zero and span over the compensated range |

| Shock Resistance: | 100G, 11mSec |

| Vibration Resistance: | 10G peak, 20-2000Hz |

| Stability (one year): | ±0.25% of full scale |

| Hazardous Location: | CSA approved to standards CSA 30 and U.L.1203; explosion-proof for Class 1, Div 1, Groups A, B, C, and D; and Div 2, Groups A, B, C, and D |

| Output: | 4…20 mA, 2-wire |

| Power Supply: | 10…28 VDC |

| Max. Loop Load: | 800Ω |

| Electrical Connection: | 1/2″ NPT conduit with 6 ft. wire leads |

| Electrical Protection: | NEMA 4X, IP 66 |

WJF Instrumentation Ltd.

#5 3610 – 29th Street N.E.

Calgary, Alberta

Canada

T1Y 5Z7

Calgary Head Office

Toll-Free: (877)291-5572

Standard: (403)291-5570

Ontario & Maritimes Sales:

(905)809-6918