Home > Temperature > Digital Temperature Gauge

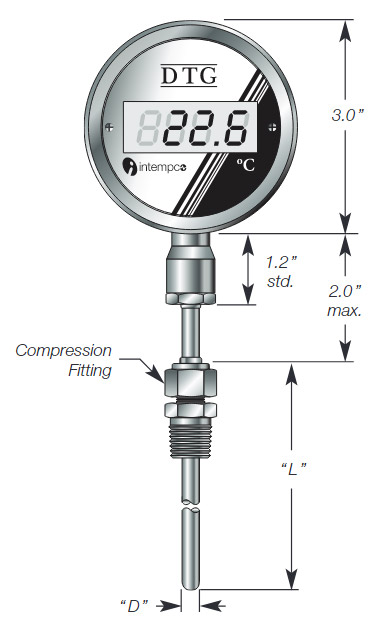

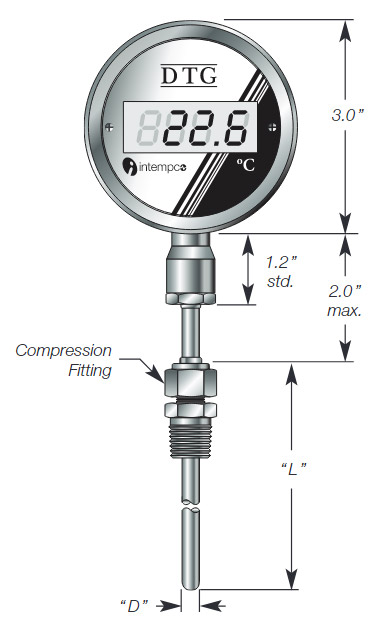

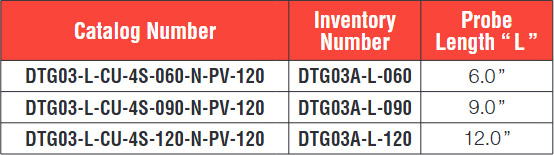

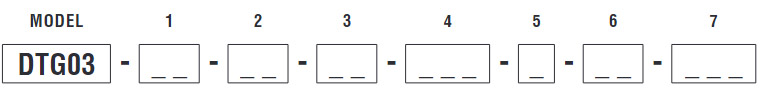

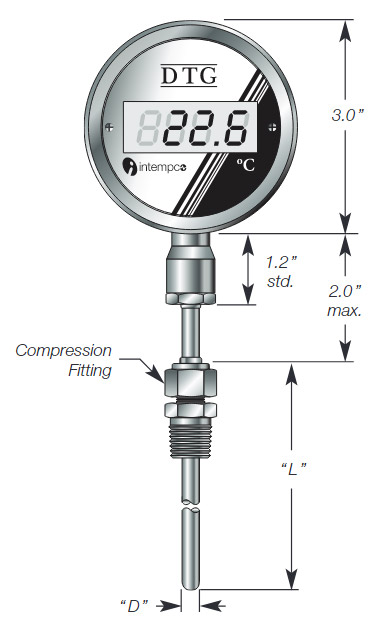

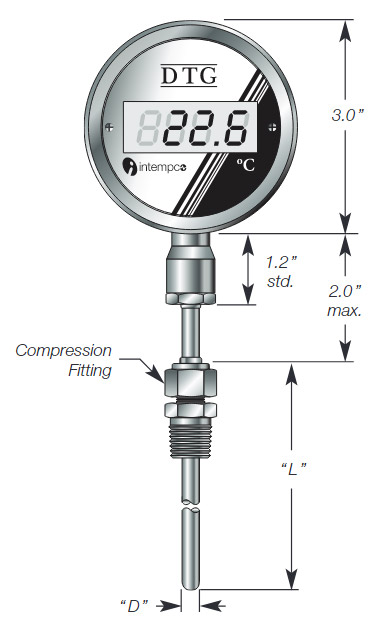

Digital Temperature Gauge with a top mount display with an adjustable compression fitting process connection the DTG03 Digital Temperature Gauge is a Digital RTD thermometer and a complete solution for most industrial temperature monitoring and temperature indicating applications.

Stainless steel construction with an analog 4-20 mA output based on Intempco’s patented MIST™ technology for optimum accuracy and repeatable performance. DTG is an ideal replacement for bi-metal,liquid bulb, mercury and capillary gas thermometers.

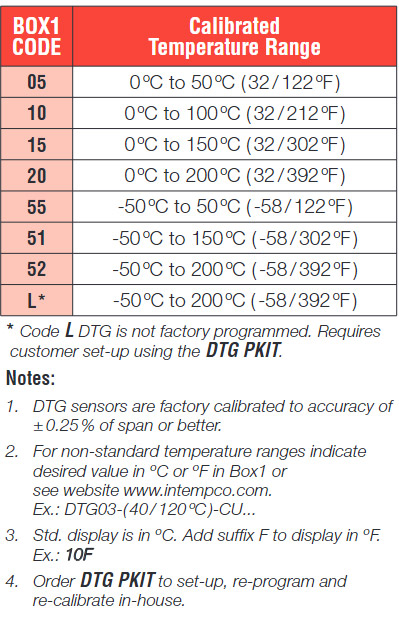

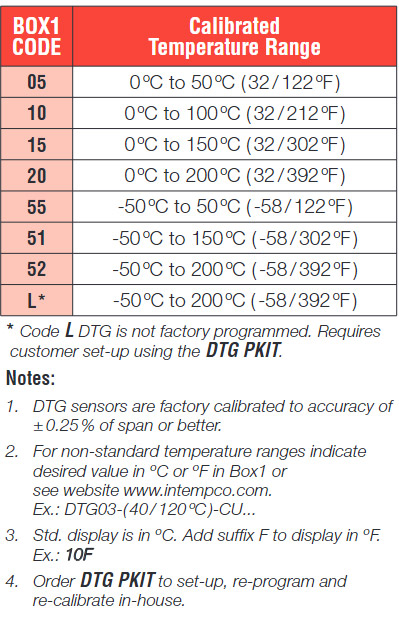

DTG03’s can be factory calibrated to customer specified temperature range. DTG’s built-in programmable transmitter can be re-scaled and re-calibrated in the field using the optional interface software.

The DTG arrives factory scaled and calibrated to the customer’s specified temperature range. No costly field calibration is required.

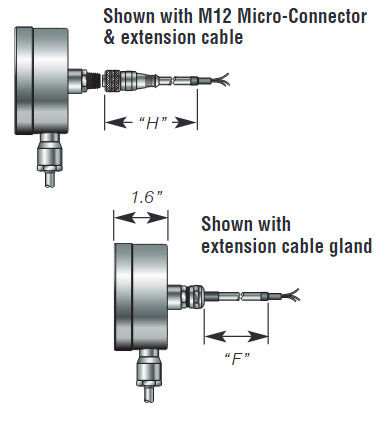

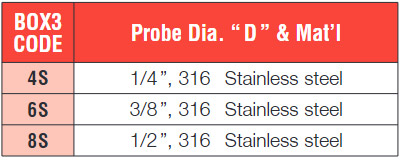

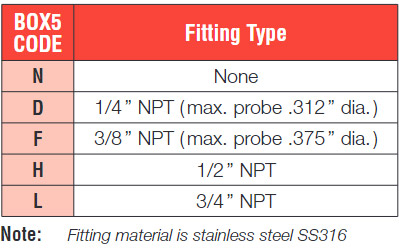

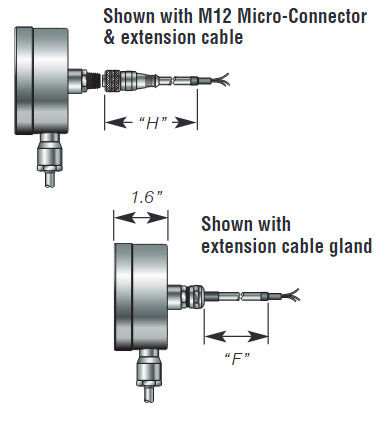

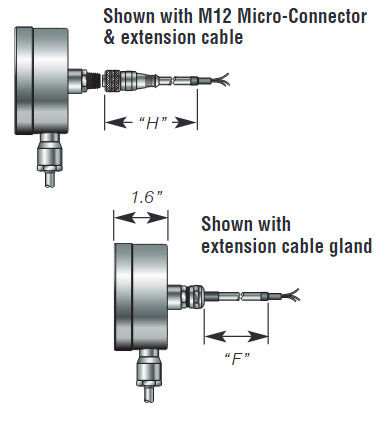

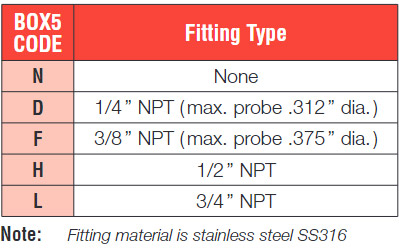

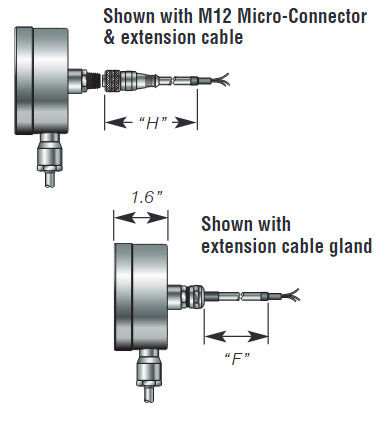

Housing, probe and fitting material is all fabricated from 316 Stainless Steel and rated to NEMA 4X ( IP65 ). Many display probe mounting configurations are available some with M12 Male output connectors.

Certain features of this product are covered under US Patent no.: 7,233,014

Installation requirements of the DTG are similar to those of the temperature sensor assemblies with head mounted hockey puck transmitter and display. If the temperature of the electronics in the housing exceeds 80 º C, permanent damage to the DTG will occur. In all applications, especially when they exceed 200 º C, careful attention must be placed on correct installation. For these applications, a remote probe wall mount unit or remote probe panel mount unit, may be a better choice. It is the installer’s, customer’s and/or end user’s responsibility to make sure that this over exposure to temperature does not occur due to improper installation.

| Sensing Element | RTD, Type Pt100 Class A |

| Temperature Ranges | Customer re-scalable between –200 o C to 600 o C or –50 o C to 200 o C depending model. No re-calibration required. |

| Switching Ranges | Customer programmable between –200 o C to 600 o C or –50 o C to 200 o C depending model. |

| Hysteresis | Customer programmable, 1% of range by factory setting. |

| Accuracy | ± ( 0.25 o C + 0.40 % of reading ) max. with default calibration. ± ( 0.10 o C + 0.20 % of reading ) max. with one-point factory or customer calibration. |

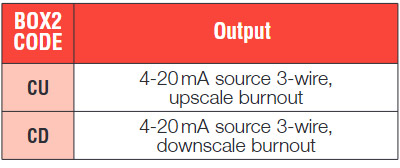

| Open circuit detection | Upscale ( 22 mA ) or Downscale ( 2.5 mA ) current output. Error message on LED display. |

| Warm-up | 30 seconds. |

| Response Time | 0.5 sec to 30 sec ( software selectable ) |

| Display | 4-DIGITS LED, decimal point selectable by software. |

| Display resolution | ± 0.02 % F.S. ±1 DIGIT |

| RFI effect | 1 % or less typical |

| Temp. Effect | < 0.01 % FS/ o C |

| Ambient Temp. Range | – 40 o C to 80 o C ( -40 o F to 176 o F ) |

| Storage Temp. Range | – 50 o C to 85 o C ( -58 o F to 185 o F ) |

| Max. Pressure | 500 PSIG ( on probe ) |

| Housing Material | Stainless steel 316 |

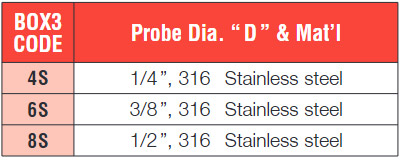

| Probe Material | Stainless steel 316 standard |

| Cable Materials | PVC, Teflon®, Silicone, SS armored Teflon® |

| Environmental Protection | NEMA 4/IP 65 |

| ELE CTRICAL | |

| Power Supply | 9-36 VDC, polarity protected |

| Supply effect | 0.005 %/V |

| Power consumption | 15 mA @ 24 VDC + output current – 950 mW max. 20 mA @ 24 VDC for PNP output – 500 mW max. 20 mA @ 24 VDC + sourcing current for NPN output 50 mA @ 24 VDC for Relay Output – 1200 mW max. |

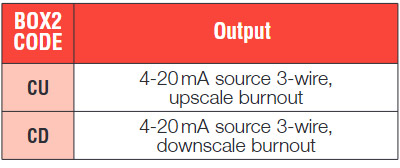

| Current Output | 4-20 mA (3 wires configuration) linear to temperature. |

| Max load on current output | ( Vsupply-9V )/ 20 mA, Ohms |

| Switching Output | Transistor NPN ( max 100 mA source ) or Transistor PNP (max 100mA sink) or Relay SPDT 0.5A @ 240 VAC |

| Switching Logic | N.C. or N.O. Software selectable. |

| Isolation | 500 VDC Input / Output ( between probe and output signal ) |

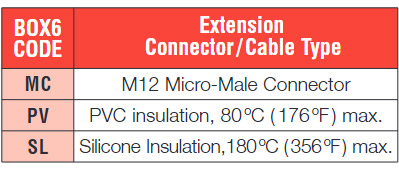

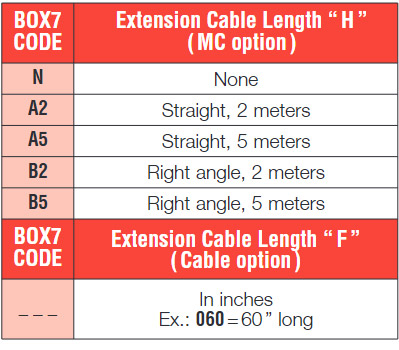

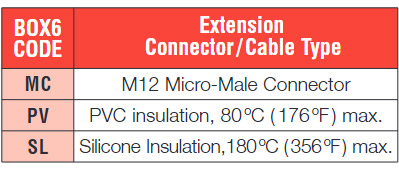

| Electrical Connection | Micro-DC male plug or cable only |

Teflon ® is a registered trademark of E.I. du Pont de Nemours and Company.

1. Max. error on complete span. Error at calibration point ≤ 0.1 % of Span.

2. Max. error on complete calibrated span. Error at calibration points ≤ 0.1 % of Span.

3. Intempco sanitary sensors bearing the 3-A symbol meet the requirements of 3-A Sanitary Standards for Sensors and Sensor Fittings and Connections,

Number 74-03, with some exceptions to section D10 for heat sterilization systems . Intempco sensors meet the requirements of section D10.1 and D10.1.1

for sterilization of the product contact surfaces, with exception made for section D10.1.2 and D10.1.3. Intempco sensors do not have a steam or other

sterilization chamber surrounding the joint at the product contact surfaces between the fitting and the devices.

• Information furnished by Intempco is believed to be accurate and reliable. However, no responsibility is assumed by Intempco for its use.

• Specifications subject to change without notice

Digital Temperature Gauge with a top mount display with an adjustable compression fitting process connection the DTG03 Digital Temperature Gauge is a Digital RTD thermometer and a complete solution for most industrial temperature monitoring and temperature indicating applications.

Stainless steel construction with an analog 4-20 mA output based on Intempco’s patented MIST™ technology for optimum accuracy and repeatable performance. DTG is an ideal replacement for bi-metal,liquid bulb, mercury and capillary gas thermometers.

DTG03’s can be factory calibrated to customer specified temperature range. DTG’s built-in programmable transmitter can be re-scaled and re-calibrated in the field using the optional interface software.

The DTG arrives factory scaled and calibrated to the customer’s specified temperature range. No costly field calibration is required.

Housing, probe and fitting material is all fabricated from 316 Stainless Steel and rated to NEMA 4X ( IP65 ). Many display probe mounting configurations are available some with M12 Male output connectors.

Certain features of this product are covered under US Patent no.: 7,233,014

Installation requirements of the DTG are similar to those of the temperature sensor assemblies with head mounted hockey puck transmitter and display. If the temperature of the electronics in the housing exceeds 80 º C, permanent damage to the DTG will occur. In all applications, especially when they exceed 200 º C, careful attention must be placed on correct installation. For these applications, a remote probe wall mount unit or remote probe panel mount unit, may be a better choice. It is the installer’s, customer’s and/or end user’s responsibility to make sure that this over exposure to temperature does not occur due to improper installation.

| Sensing Element | RTD, Type Pt100 Class A |

| Temperature Ranges | Customer re-scalable between –200 o C to 600 o C or –50 o C to 200 o C depending model. No re-calibration required. |

| Switching Ranges | Customer programmable between –200 o C to 600 o C or –50 o C to 200 o C depending model. |

| Hysteresis | Customer programmable, 1% of range by factory setting. |

| Accuracy | ± ( 0.25 o C + 0.40 % of reading ) max. with default calibration. ± ( 0.10 o C + 0.20 % of reading ) max. with one-point factory or customer calibration. |

| Open circuit detection | Upscale ( 22 mA ) or Downscale ( 2.5 mA ) current output. Error message on LED display. |

| Warm-up | 30 seconds. |

| Response Time | 0.5 sec to 30 sec ( software selectable ) |

| Display | 4-DIGITS LED, decimal point selectable by software. |

| Display resolution | ± 0.02 % F.S. ±1 DIGIT |

| RFI effect | 1 % or less typical |

| Temp. Effect | < 0.01 % FS/ o C |

| Ambient Temp. Range | – 40 o C to 80 o C ( -40 o F to 176 o F ) |

| Storage Temp. Range | – 50 o C to 85 o C ( -58 o F to 185 o F ) |

| Max. Pressure | 500 PSIG ( on probe ) |

| Housing Material | Stainless steel 316 |

| Probe Material | Stainless steel 316 standard |

| Cable Materials | PVC, Teflon®, Silicone, SS armored Teflon® |

| Environmental Protection | NEMA 4/IP 65 |

| ELE CTRICAL | |

| Power Supply | 9-36 VDC, polarity protected |

| Supply effect | 0.005 %/V |

| Power consumption | 15 mA @ 24 VDC + output current – 950 mW max. 20 mA @ 24 VDC for PNP output – 500 mW max. 20 mA @ 24 VDC + sourcing current for NPN output 50 mA @ 24 VDC for Relay Output – 1200 mW max. |

| Current Output | 4-20 mA (3 wires configuration) linear to temperature. |

| Max load on current output | ( Vsupply-9V )/ 20 mA, Ohms |

| Switching Output | Transistor NPN ( max 100 mA source ) or Transistor PNP (max 100mA sink) or Relay SPDT 0.5A @ 240 VAC |

| Switching Logic | N.C. or N.O. Software selectable. |

| Isolation | 500 VDC Input / Output ( between probe and output signal ) |

| Electrical Connection | Micro-DC male plug or cable only |

Teflon ® is a registered trademark of E.I. du Pont de Nemours and Company.

1. Max. error on complete span. Error at calibration point ≤ 0.1 % of Span.

2. Max. error on complete calibrated span. Error at calibration points ≤ 0.1 % of Span.

3. Intempco sanitary sensors bearing the 3-A symbol meet the requirements of 3-A Sanitary Standards for Sensors and Sensor Fittings and Connections,

Number 74-03, with some exceptions to section D10 for heat sterilization systems . Intempco sensors meet the requirements of section D10.1 and D10.1.1

for sterilization of the product contact surfaces, with exception made for section D10.1.2 and D10.1.3. Intempco sensors do not have a steam or other

sterilization chamber surrounding the joint at the product contact surfaces between the fitting and the devices.

• Information furnished by Intempco is believed to be accurate and reliable. However, no responsibility is assumed by Intempco for its use.

• Specifications subject to change without notice

WJF Instrumentation Ltd.

#5 3610 – 29th Street N.E.

Calgary, Alberta

Canada

T1Y 5Z7

Calgary Head Office

Toll-Free: (877)291-5572

Standard: (403)291-5570

Ontario & Maritimes Sales:

(905)809-6918