Home > Temperature > Dial Thermometers

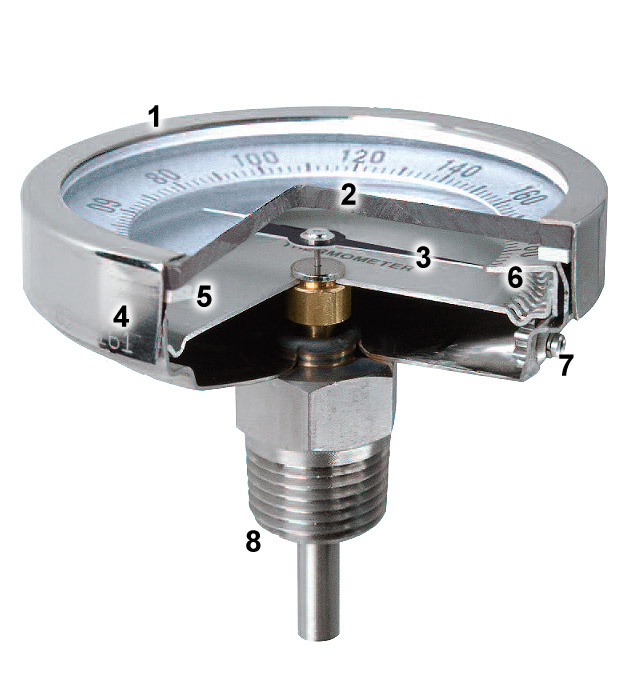

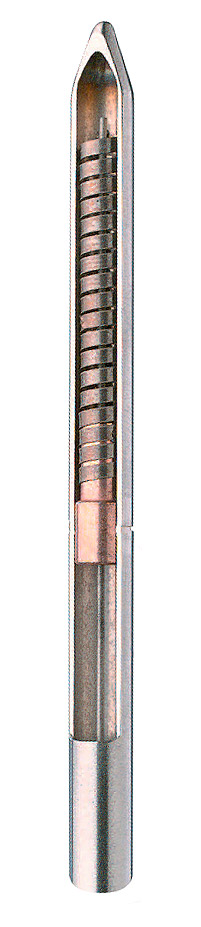

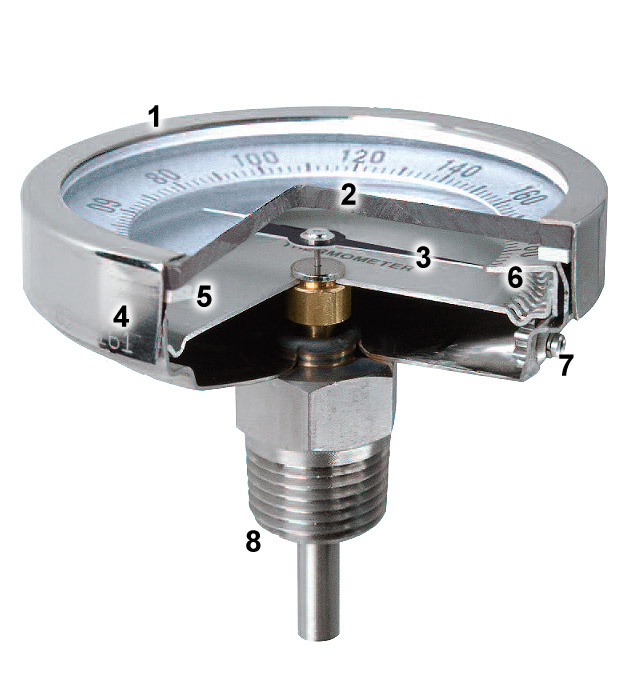

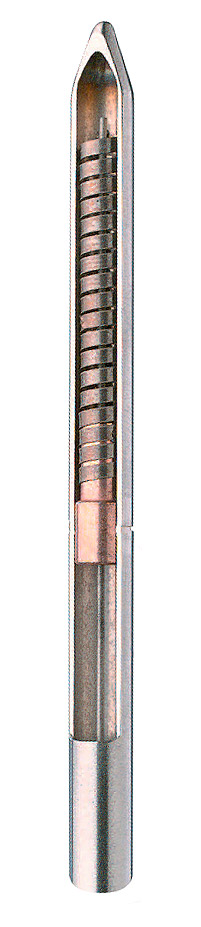

Dial Thermometers are mechanical temperature indicators consisting of a pointer precisely connected to a bimetal helix stem which moves due to temperature changes in the bimetal helix. It is fabricated with extreme tolerances, which results in a very sensitive temperature reading.

An anti-parallax dial is used with a concave design of the dial ring to enhance readability. Graduations for each temperature range are calculated to match deflection data of bimetallic materials. Stainless steel housing is used for corrosion resistance and the complete assembly is hermetically sealed.

| Stem Lengths | 2.5”, 4”, 6”, 9” 12”, 15” and 24” are standard ( available up to 120” ) |

| Stem Diameter | 0.250” for “U” ≤ 42”, 0.375” for “U” > 42” |

| Connection | 1/2” NPT standard |

| Construction | 304 stainless steel external parts. Welded construction. SS316 available Corrosion resistant to most chemicals. |

| Hermetic Seal | Per ASME B40.3 dusproof and leakproof |

| Dial | True Anti-Parallax dial, easy-to-read from any angle, minimizes reading errors. Anodized aluminum with large black numbers and graduations. |

| Lens | Glass standard |

| Bimetal Coil | Helix coil is silicone coated on ranges below 500 ºF for vibration dampening and to maximize heat transfer and response time. |

| Accuracy | ± 1% of full span per ASME B40.3 Grade A |

| Calibration Feature | Standard on BTG01 Series |

| External Reset | Easy to calibrate by inserting Allen wrench into reset opening |

| Over Temperature Limits | • 100% : For ranges up to 121°C ( 250 °F ) • 50% : For ranges 121°C to 289 °C ( 250 °F to 550 °F ) • For ranges 289 °C to 538 °C ( 550 °F to 1000 °F ): up to 427 °C ( 800 °F ) for continous use, intermittent use over 427 °C ( 800 °F ) |

Dial Thermometers are mechanical temperature indicators consisting of a pointer precisely connected to a bimetal helix stem which moves due to temperature changes in the bimetal helix. It is fabricated with extreme tolerances, which results in a very sensitive temperature reading.

An anti-parallax dial is used with a concave design of the dial ring to enhance readability. Graduations for each temperature range are calculated to match deflection data of bimetallic materials. Stainless steel housing is used for corrosion resistance and the complete assembly is hermetically sealed.

| Stem Lengths | 2.5”, 4”, 6”, 9” 12”, 15” and 24” are standard ( available up to 120” ) |

| Stem Diameter | 0.250” for “U” ≤ 42”, 0.375” for “U” > 42” |

| Connection | 1/2” NPT standard |

| Construction | 304 stainless steel external parts. Welded construction. SS316 available Corrosion resistant to most chemicals. |

| Hermetic Seal | Per ASME B40.3 dusproof and leakproof |

| Dial | True Anti-Parallax dial, easy-to-read from any angle, minimizes reading errors. Anodized aluminum with large black numbers and graduations. |

| Lens | Glass standard |

| Bimetal Coil | Helix coil is silicone coated on ranges below 500 ºF for vibration dampening and to maximize heat transfer and response time. |

| Accuracy | ± 1% of full span per ASME B40.3 Grade A |

| Calibration Feature | Standard on BTG01 Series |

| External Reset | Easy to calibrate by inserting Allen wrench into reset opening |

| Over Temperature Limits | • 100% : For ranges up to 121°C ( 250 °F ) • 50% : For ranges 121°C to 289 °C ( 250 °F to 550 °F ) • For ranges 289 °C to 538 °C ( 550 °F to 1000 °F ): up to 427 °C ( 800 °F ) for continous use, intermittent use over 427 °C ( 800 °F ) |

WJF Instrumentation Ltd.

#5 3610 – 29th Street N.E.

Calgary, Alberta

Canada

T1Y 5Z7

Calgary Head Office

Toll-Free: (877)291-5572

Standard: (403)291-5570

Ontario & Maritimes Sales:

(905)809-6918