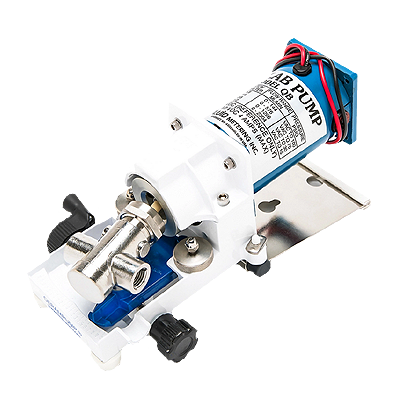

FMI Chemical Injection Pump QB Series Direct Current version For Mobile, Remote & Instrumentation. Part of a complete line of FMI Pumps for metering & dispensing Systems, all of which deliver a high level of precision and accuracy.

Utilized in a vast range of industries including Medical, Laboratory, Analytical, and Industrial Process applications.

FMI Pumps feature the patented CeramPump® valveless piston pumping technology. The CeramPump® positive displacement design has one moving part in the fluid path, a sapphire-hard ceramic piston to perform all fluid control functions.

The elimination of valves minimizes downtime or the need for re-calibration and our long term drift-free performance delivers millions of “trouble-free” cycles at 1% precision or better.

| Spec | Value |

|---|---|

| Rating | QB PUMPS: Rated at 1800 RPM (or approximately 8 volts for 12 V DC models) |

| Dimensions | 10 1/2″ x 5″ x 4 1/2″ wide (267 x 127 x 114 mm) |

| Shipping Weight | 8 lb (3.6kg) |

| Electrical | 12 V DC, 4 amps; 24 V DC, 3 amps; 90 V DC, 0.41 amps, totally enclosed with 6″ pigtail leads Shaft extension: 5/16″ dia. x 1″ long with flat |

| Drive Options | Mounting Base Part # -MB, Dial Indicator Part # Q485, 24 VDC (3 amps) Part # -4, 90 VDC (0.41 amps) Part # -5 |

| Max Min Flow Rate (ML/MIN) | 45 to 2304* |

| Pressure | 25 to 100 PSIG |

*GENERAL SPECIFICATION NOTES FOR ALL PUMPS

| MAX. Flow/Pressure | Pump Drive Module | Piston Code | ||

|---|---|---|---|---|

| ML/MIN | PSIG | BAR | ||

| 45 | 100 | 6.90 | QB | RH00 |

| 90 | RH0 | |||

| 144 | Q0 | |||

| 180 | RH1 | |||

| 576* | 70 | 4.38 | Q1 | |

| 1296* | 30 | 2.07 | Q2 | |

| 2304* | 25 | 1.72 | Q3 | |

| QB Drive Options |

|---|

| Mounting Base Part # -MB |

| Dial Indicator Part # Q485 |

| 24 VDC (3 amps) Part # -4 |

| 90 VDC (0.41 amps) Part # -5 |

On all pumps, flow rates may be altered when operating or at rest. On the “Q” line this is done by turning the Flow Control Knob which moves the flow rate indicator along a fixed 20 unit scale linearly calibrated “10-0-10”. The “10” equals 100% flow rate in that direction, “0” equals zero flow. To improve the fine adjustment of the flow rates on the “Q” line, there is an optional Dial Indicator Kit Q485 which provides for 1000 discrete settings. The “RH” line flow adjustment is accomplished by turning an easy-grip Flow Control Ring graduated in 450 divisions from 0 to 100% flow.

Yes. Pumps will self prime to 15 feet vertical dry, 26 feet wet.

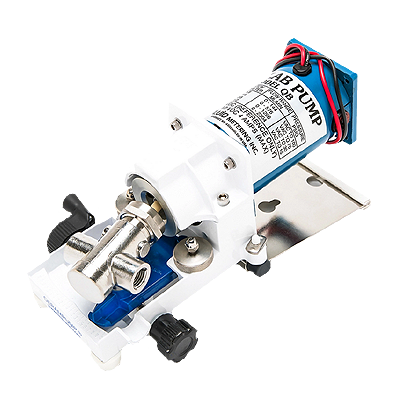

FMI Chemical Injection Pump QB Series Direct Current version For Mobile, Remote & Instrumentation. Part of a complete line of FMI Pumps for metering & dispensing Systems, all of which deliver a high level of precision and accuracy.

Utilized in a vast range of industries including Medical, Laboratory, Analytical, and Industrial Process applications.

FMI Pumps feature the patented CeramPump® valveless piston pumping technology. The CeramPump® positive displacement design has one moving part in the fluid path, a sapphire-hard ceramic piston to perform all fluid control functions.

The elimination of valves minimizes downtime or the need for re-calibration and our long term drift-free performance delivers millions of “trouble-free” cycles at 1% precision or better.

| Spec | Value |

|---|---|

| Rating | QB PUMPS: Rated at 1800 RPM (or approximately 8 volts for 12 V DC models) |

| Dimensions | 10 1/2″ x 5″ x 4 1/2″ wide (267 x 127 x 114 mm) |

| Shipping Weight | 8 lb (3.6kg) |

| Electrical | 12 V DC, 4 amps; 24 V DC, 3 amps; 90 V DC, 0.41 amps, totally enclosed with 6″ pigtail leads Shaft extension: 5/16″ dia. x 1″ long with flat |

| Drive Options | Mounting Base Part # -MB, Dial Indicator Part # Q485, 24 VDC (3 amps) Part # -4, 90 VDC (0.41 amps) Part # -5 |

| Max Min Flow Rate (ML/MIN) | 45 to 2304* |

| Pressure | 25 to 100 PSIG |

*GENERAL SPECIFICATION NOTES FOR ALL PUMPS

| MAX. Flow/Pressure | Pump Drive Module | Piston Code | ||

|---|---|---|---|---|

| ML/MIN | PSIG | BAR | ||

| 45 | 100 | 6.90 | QB | RH00 |

| 90 | RH0 | |||

| 144 | Q0 | |||

| 180 | RH1 | |||

| 576* | 70 | 4.38 | Q1 | |

| 1296* | 30 | 2.07 | Q2 | |

| 2304* | 25 | 1.72 | Q3 | |

| QB Drive Options |

|---|

| Mounting Base Part # -MB |

| Dial Indicator Part # Q485 |

| 24 VDC (3 amps) Part # -4 |

| 90 VDC (0.41 amps) Part # -5 |

On all pumps, flow rates may be altered when operating or at rest. On the “Q” line this is done by turning the Flow Control Knob which moves the flow rate indicator along a fixed 20 unit scale linearly calibrated “10-0-10”. The “10” equals 100% flow rate in that direction, “0” equals zero flow. To improve the fine adjustment of the flow rates on the “Q” line, there is an optional Dial Indicator Kit Q485 which provides for 1000 discrete settings. The “RH” line flow adjustment is accomplished by turning an easy-grip Flow Control Ring graduated in 450 divisions from 0 to 100% flow.

Yes. Pumps will self prime to 15 feet vertical dry, 26 feet wet.

WJF Instrumentation Ltd.

#5 3610 – 29th Street N.E.

Calgary, Alberta

Canada

T1Y 5Z7

Calgary Head Office

Toll-Free: (877)291-5572

Standard: (403)291-5570

Ontario & Maritimes Sales:

(905)809-6918