Understanding LEL Detection

Gas mixtures are considered “too lean” to burn when present in air at a concentration below the Lower Explosive Limit (LEL). In theory the LEL of methane gas is 4.4% of atmospheric air. Even in the presence of an ignition source, an explosion cannot happen below the LEL of 4.4% of methane in air. However, if an LEL monitor detects levels above the 4.4% threshold, it will trigger an over limit condition which in turn may trigger other actions such as alarms, visual beacons and automatic ventilation systems. Workers will be instructed to leave the area immediately upon hearing any alarms.

Which Industries Use LEL Monitors

The primary users of an LEL Monitor, are the Oil and Gas industries, but they are used in any situation where explosive gases can concentrate to dangerous levels. To keep workers safe over the course of their shift, it is essential to be able to detect potentially explosive gases and alert workers of the danger.

The use of Lower Explosive Limits monitors, or LEL monitors, to do this is essential.

These gas detectors are essential components of any industrial safety plan, because they are made to detect flammable gas levels before they rise to dangerous levels that might cause fires or explosions.

They are used in a number of contexts, including offshore oil drilling platforms, gas pipelines, and in refineries or industrial plants.

Different types of LEL Gas Detection

LEL monitor (s) can be divided into systems and detection methods. The main systems are fixed gas detectors and a personal (portable) gas monitor. Other systems include inline gas detection and portable leak “sniffers”.

The two main detection methods are IR (infrared) LEL Sensors and catalytic ‘Wheatstone bridge’ (sometimes call Catalytic-bead or Cat-bead sensors). First impressions would suggest that IR sensors are the best options as they are more reliable, cheaper and lower powered, but further investigation will show that each type has it’s advantages and disadvantages.

Catalytic-bead Sensors: LEL Gas detection by catalytically oxidizing the gas on an active bead located within the sensor which is registered by the instrument as a change in electrical resistance.

The temperature of the active bead must be high enough for the gas to be oxidized which leads to higher power consumption to heat the bead area. Catalytic LEL sensors also require the presence of oxygen. Typically, LEL sensors cannot be used if the concentration of oxygen O2 is less than 10%. Therefore this is one limitation to their use and where an IR sensor will be required.

Catalytic-bead sensors respond to a wide range of flammable gases and vapors. However, they can be “poisoned” by the presence of sulfur, phosphorus, or vapors that contain silicones.

IR (infrared): The three main benefits of an IR sensor are, lower power consumption, operation in low oxygen environments and the inability to be poisoned. IR sensors can also differentiate between different target gases.

A disadvantage is they cannot detect some combustible gasses like Hydrogen.

Regardless of the sensor chosen, it is important to understand which target gasses can potentially be present and ensure that your detector is able to monitor them safely.

Looking at a broad comparison, a catalytic bead sensor is usually calibrated to detect methane and sometimes propane. It can then be “corrected” to detect other types of gases. Generally speaking a catalytic bead sensor will react to a wide range of combustible gasses. An IR sensor is calibrated (usually at the factory) to detect a narrow range of specific gas types, so does not “see” other gases. It cannot see some gasses like Hydrogen or acetylene.

Correct selection will depend on the environment where the sensor will be located.

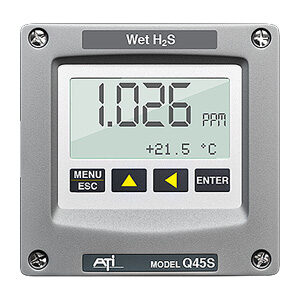

How to Calibrate an LEL Gas Detector

Each LEL meter, LEL monitor, LEL sensor and LEL gas detector will have different menu systems to facilitate calibration. Refer to each instruments manual and ensure the correct procedure is followed. However, each process will follow the same basic goal. The calibrate the most common target calibration gas used is Methane. A calibration gas bottle will be used with a regulator and tubing to deliver a known amount of methane to the instrument. A test is then performed to establish if the instrument “sees” the target gas and responds correctly. Adjustments, replacements or maintenance is then performed as required.