Chemical feed pumps powered by advanced microprocessor-based electronics and superior mechanical design. Feed pumps that will fit most any industrial, municipal, agricultural water or wastewater applications.

- Most Versatile Water Treatment Chemical Feed Pump. (Max. 20 GPH, 150 PSI)

- Water Treatment and OEM Electronic Metering Pump. (Max. 6.3 GPH, 150PSI)

- High Speed Dosing Pump - Virtually Any Chemical Feed Application. (0.5 to 1.7 GPH. 290 PSI)

- Flow Sensor Controlled for Real Time Control (Max. 1.59 GPH, 150 PSI)

- Lowest Cost, High Performance. (Max 1.3. GPH, 175 PSI)

- Energy Efficient Metering Pump. 70% Savings (Max. 40 GPH)

- High Capacity Motor Driven (Max. 114 GPH, 225 PSI)

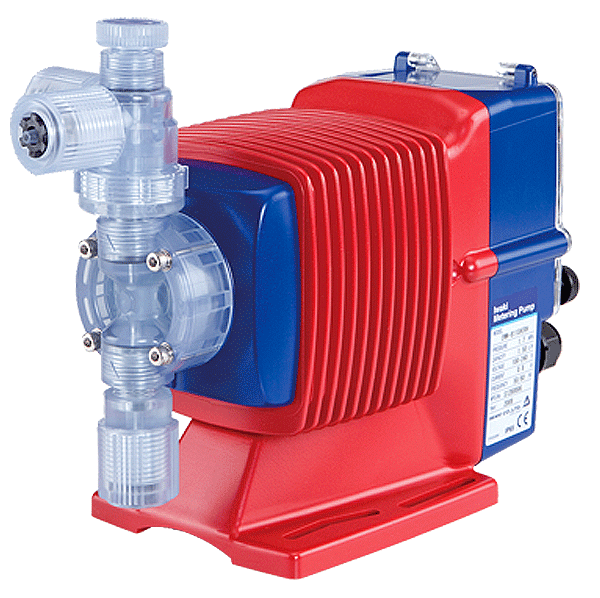

The Most Versatile Chemical Feed Pump in Water Treatment – EH Series Superior Mechanical Feed Pump.

The EHE is the workhorse of the E-Class metering pumps. EHE Series pumps have outputs up to 20 GPH (75 l/h) and pressure capabilities to 150 PSI (10 bar).

- Up to 360 spm high resolution feed

- Dual bearing support

- Dual check valve assembly.

- Digital display and 4-button keypad

- Flow rates up to 20 GPH

Combining the EHE performance with a turndown ratio of 1800:1 yields one of the most versatile pumps in the water treatment industry today. Superior mechanical design and quality of manufacturing merge to create a pump better than the sum of its parts. The versatile control features enable the EHE to be inte-grated into virtually any chemical feed application. The 360 stroke-per-minute operation results in high-resolution chemical feed and long service life. EHE pumps prime in seconds and hold prime reliably.

- High Speed Performance

E-Class pumps operate at 360 strokes-per-minute, providing high resolution chemical feed. Most competitive products operate at slower speeds, resulting in slug feeding, accelerated diaphragm wear and poor feed control. - Engineered Longevity

All E-Class pumps feature dual bearing support. The armature and shaft are supported with a bearing on each end, which ensures proper axial movement, enabling the E-Class to operate at 360 SPM while extending the life of the diaphragm. - Superior Check Valve Performance

Dual Check Valve Assemblies in both suction and discharge fittings feature precision ball guides and tapered seats. Precise machining and molding of parts limit valve ball travel, ensuring that balls fully seat and seal with every stroke. This superior check valve design guarantees fast priming and reliable performance. - High Compression Ratio

The compression ratio of a metering pump is important because it affects the pump’s ability to prime and vent. The compression ratio is raised when you reduce the dead volume of the pump head during operation. All E-Class pumps feature a very high compression ratio that ensures proper feed especially with off-gassing products (i.e. Sodium Hypochlorite).

Call 1-877 291 5572 for pump consultation and configuration questions.

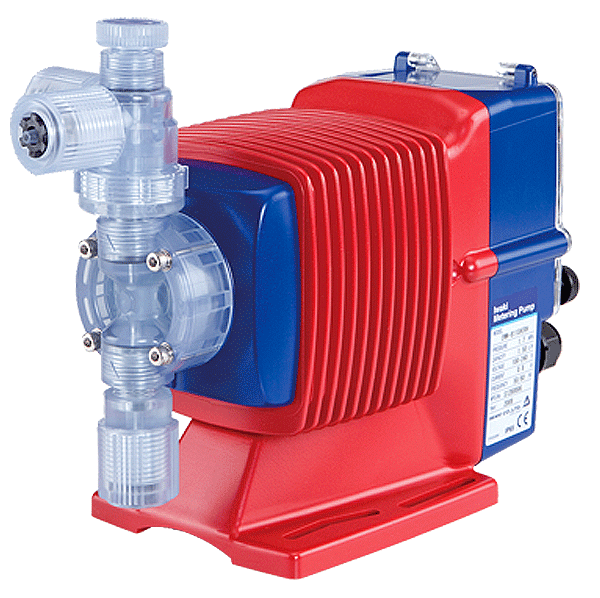

Ideal for Water Treatment and OEM Applications – EZ Series Electronic Metering Chemical Feed Pump.

EZ Series electronic metering pumps offer precise chemical feed injection at a low cost. The compact size and simple control make them ideal for water treatment and OEM applications

- Low-Cost High Performance Pump

- Up to 360 spm High Resolution Feed

- Digital Display and 4-Button Keypad

- Flow Rates up to to 6.3 GPH

- Pressures up to 150 psi

- Timer Control Module Option

EZ Series have outputs to 6.3 GPH (24 l/h) and a maximum pressure of 150 PSI ( 10 bar). Advanced microprocessor control and a turndown ratio of 360:1 make this series an exceptional value. The pumps are simple to operate with only three pushbutton keys and the unmatched turndown ratio provides both versatility and high resolution chemical feed which eliminates slug-feeding effects.

- High Speed Performance E-Class pumps operate at 360 strokes-per-minute, providing high resolution chemical feed. Most competitive products operate at slower speeds, resulting in slug feeding, accelerated diaphragm wear and poor feed control.

- Engineered Longevity

All E-Class pumps feature dual bearing support. The armature and shaft are supported with a bearing on each end, which ensures proper axial movement, enabling the E-Class to operate at 360 SPM while extending the life of the diaphragm. - Superior Check Valve Performance

Dual Check Valve Assemblies in both suction and discharge fittings feature precision ball guides and tapered seats. Precise machining and molding of parts limit valve ball travel, ensuring that balls fully seat and seal with every stroke. This superior check valve design guarantees fast priming and reliable performance. High Compression Ratio The compression ratio of a metering pump is important because it affects the pump’s ability to prime and vent. The compression ratio is raised when you reduce the dead volume of the pump head during operation. All E-Class pumps feature a very high compression ratio that ensures proper feed especially with off-gassing products (i.e. Sodium Hypochlorite). - Innovative Timer Control

The EZ-Timer module integrates Walchem’s EZB pump technology with a versatile programmable timer. Timed feed control can be programmed in daily or weekly cycles.

Call 1-877 291 5572 for pump consultation and configuration questions.

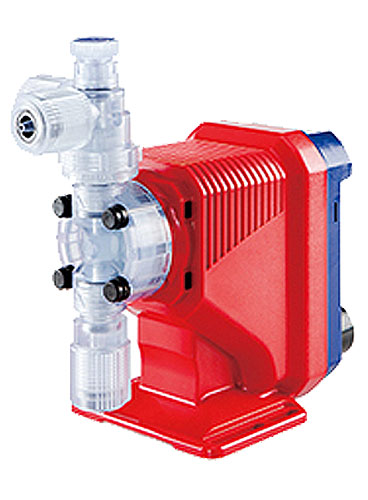

Superior High Speed Dosing – The EWN-R Series Electronic Chemical Feed Metering Pump

The EWN-R Series electronic metering pumps offer superior high speed dosing capability with more standard features. The flexibility of the EWN-R pump enable it be integrated into virtually any chemical feed application using a universal-voltage, digital controller with an expanded set of control features.

- Up to 360 spm High Resolution Feed

- Digital Display and 5-Button Keypad

- Flow Rates from 0.5 to 1.7 GPH

- Pressures up to 290 PSI

- Optional Feed Verification

Superb valve performance and advanced solenoid engineering combine to make a highly precise pump for the most demanding applications. EWN pumps have outputs to 6.7 GPH (25.2 L/h) and a maximum pressure of 250 PSI (17 bar). The high speed of operation results in high resolution chemical feed pumping and long service life. Quiet and compact, the EWN pump prime in seconds and hold prime reliably.

- High Speed Performance

E-Series pumps operate up to 360 strokes-per-minute with adjustments in 1 spm increments, providing high resolution chemical feed. Adjustable stroke length further increases the ability to refine output, making the E-Series one of the most versatile solenoid metering pumps on the market. - Multi-function Digital Controller

The controller in the EWN-R pump provides for flexible pump control including scalable Analog control, Digital Input with both Multiply and Divide capability, external stop control, or simple speed and stroke length control. Display can be adjusted between flow rate units or % speed for easy-to-read output and quick adjustment. The controller is universal voltage so it can be used anywhere in the world. - Engineered Longevity

All E-Series pumps feature dual bearing support. The armature and shaft are supported with a bearing on each end, which ensures proper axial movement, enabling the E-Series to operate at 360 SPM while extending the life of the diaphragm. - Superior Check Valve Performance

Dual Check Valve Assemblies in both suction and discharge fittings feature precision ball guides and tapered seats. Precise machining and molding of parts limit valve ball travel, ensuring that balls fully seat and seal with every stroke. This superior check valve design guarantees fast priming and reliable performance. - Flexible Connections

A removable tubing insert provides flexibility of tubing sizes and eliminates twisting of the tubing during connection. A threaded insert can be used in place of the tubing adapter to easily convert any connection to NPT. - High Compression Ratio

The compression ratio of a metering pump is important because it affects the pump’s ability to prime and vent. The compression ratio is raised when you reduce the dead volume of the pump head during operation. All E-Series pumps feature a very high compression ratio that ensures proper feed especially with off-gassing products (i.e. Sodium Hypochlorite).

Call 1-877 291 5572 for pump consultation and configuration questions.

Flow Sensor Provides Precise Flow Monitoring – The EWN-Y Series Electronic Metering Chemical Feed Pump

The new EWN-Y electromagnetic pump combined with EFS flow sensor provides accurate real-time control and display of dosing rate.

- Chemical feed pump with flowmeter.

- Automatic pump speed adjustment.

- 4-20mA feedback of flow rate.

- No need for regular calibration.

- Clear display of actual dosing rate

- flow rates up to 1.59 gph

- Pressures up to 150 psi

The new EWN-Y electromagnetic pump combined with EFS flow sensor provides accurate real-time control and display of dosing rate.Set point control allows the desired flow rate to be simply programmed into the pump. Through feedback from the EFS sensor, the pump constantly adjusts its speed to maintain the set dosing rate – even under changing temperature, viscosity or suction and discharge pressure conditions.The EFS is mounted directly on the pump for accurate dosing rate measurement – ALL WITHOUT ANY TIME-CONSUMING CALIBRATION

- High Speed Performance

E-Class pumps operate at 360 strokes-per-minute, providing high resolution chemical feed. Most competitive products operate at slower speeds, resulting in slug feeding, accelerated diaphragm wear and poor feed control. - Engineered Longevity

All E-Class pumps feature dual bearing support. The armature and shaft are supported with a bearing on each end, which ensures proper axial movement, enabling the E-Class to operate at 360 SPM while extending the life of the diaphragm. - Superior Check Valve Performance

Dual Check Valve Assemblies in both suction and discharge fittings feature precision ball guides and tapered seats. Precise machining and molding of parts limit valve ball travel, ensuring that balls fully seat and seal with every stroke. This superior check valve design guarantees fast priming and reliable performance. - High Compression Ratio

The compression ratio of a metering pump is important because it affects the pump’s ability to prime and vent. The compression ratio is raised when you reduce the dead volume of the pump head during operation. All E-Class pumps feature a very high compression ratio that ensures proper feed especially with off-gassing products (i.e. Sodium Hypochlorite).

Call 1-877 291 5572 for pump consultation and configuration questions.

Lowest Cost High Performance – The EJ Series Precise Chemical Injection Pump

The EJ Series provide precise chemical injection at an economical price.

- Lowest-Cost Pump

- 360 spm High Resolution Feed

- Universal Power Voltage

- Proportional or On/Off Control

- IP65 Rating

Universal voltage capability enables operation from 100 – 240VAC in virtually all countries.The EJ Series are compact, simple to operate and have outputs to 1.3 GPH (4.8 LPH) and a maximum pressure of 175 PSI (1.2 MPa).

- High Speed Performance

The EJ Series operate at 360 strokes-per-minute, providing high resolution chemical feed and high turndown capability. Most competitive products operate at slower speeds, resulting in slug feeding, accelerated diaphragm wear and poor feed control. - Universal Voltage

The Universal Voltage Function enables the EJ Series to operate at any AC voltage. The EJ Series also conform to global standards. - External Control

The EJ Series have both digital input and Stop/Start inputs built into the pump, enabling either proportional or On/Off control. - IP65 Equivalent Protection

A robust housing protects the pump from normal wear. Mounting the Digital Display and Key Pad control within the drive housing creates a highly water resistant design. A clear cover further protects the pump from liquids.

Call 1-877 291 5572 for pump consultation and configuration questions.

Extremely Accurate, Energy Efficient Metering Pump – High Resolution IX Series Chemical Metering Pump.

IX Series are digitally controlled direct-drive diaphragm pumps. Years of experience in high-end motor technology result in extremely accurate and energy efficient metering pumps with high resolution.

- Pump rates to 40 GPH

- Fast priming, no air locking

- 6-position controller

- 70% power reduction compared to motor driven pumps.

- 750:1 turn-down.

- +- 1% high accuracy.

- 70% Energy Savings.

The IX Series meet today’s demand for automated chemical delivery in industries from water treat-ment to chemical process. Highly precise control offers a solution for a variety of dosing applications

- High Turndown Ratio Motor control adjusts the discharge and suction speeds to meet a full and accurate turndown ratio of 750:1 (150 l/h to 200 ml/h).

- High Accuracy Combined with precise motor control, an efficient valve design maintains accurate flow rates to allow a low-cost, mechanically-driven diaphragm pump to achieve a high accuracy of ±1%.

- Energy Savings Helical gears and return spring reduce power consumption by up to 70% compared to conventional mechanical diaphragm metering pumps.

- High Compression Pump Head Design A fixed stroke length maintains high compression in each stroke resulting in fast priming and no air-lock at any flow rate up to rated pressures.

Call 1-877 291 5572 for pump consultation and configuration questions.

Largest Pump with a Maximum Capacity of 114 GPH (432 l/h) and a maximum pressure of 225 PSI – The LK Series Motor Driven Metering Pump.

The LK Series metering pump is the largest in the high performance line of chemical feed pumps from Walchem Corporation.

- TEFC motor driven

- Dual cam drive with worm gear speed reducer

- Pump rates up to 114 GPH

- Optional 4-20mA control

The LK is a motor-driven, mechanically actuated diaphragm metering pump with a maximum capacity of 114 GPH (432 l/h) and a maximum pressure of 225 PSI (1.5 MPa).

The heart of the LK is a compact and very reliable dual-cam system drive and worm gear reducer. Roller bearings and oil bath lubrication ensure outstanding durability and wear resistance in continuous operation.

The LK Series is ideal for chemical feed applications in a wide range of fields, including water treatment, chemical process, agriculture, mining and paper

- Liquid Ends

Drive from the gear reduction unit is directly transferred to the diaphragm. This design is economical, yet retains a high degree of versatility. Liquid ends are available in PVC, PVDF and 316 SS for handling acids, bases, solvents, polymers and slurries. - Stroke Adjustment

Accurate and reliable stroke setting is accomplished with a micrometer dial of the springback stroke adjustment mechanism. This lockable mechanism is adjustable from 10 to 100%. - Drive

The LK utilizes a dual-cam system drive with a built-in worm gear type speed reducer. The alumi-num bronze worm gear and the tapered roller bearing provide efficient transmission of motor power to the pump. This compact and rigid mechanism provides maximum wear resistance in continuous operation over long periods of time. - Motors

All of the standard models employ totally enclosed fan-cooled motors which are vertically mounted to save space. A variety of motor options are available, including explosion-proof and DC variable speed motors for external control by a 4-20 mA input signal.

Call 1-877 291 5572 for pump consultation and configuration questions.